Customer review from Daehan in Indonesia on IoT NEXIO SYSTEM

Company Overview

Explore more information about the companyFactory Name

PT Daehan Global

Interviewee

- Mr. Jae Hyun Kim, General Production Planning

- Ms. Widya Musyarofah, Production Planning Staff

Place

Brebes, Indonesia

Number of Employees

17,000

Establishment Date

- 1996 in Bogor, Indonesia - Export especially to US and Korea

Sewing Products

- Woven items such as jackets and pants for men, women, and kids.

Interview

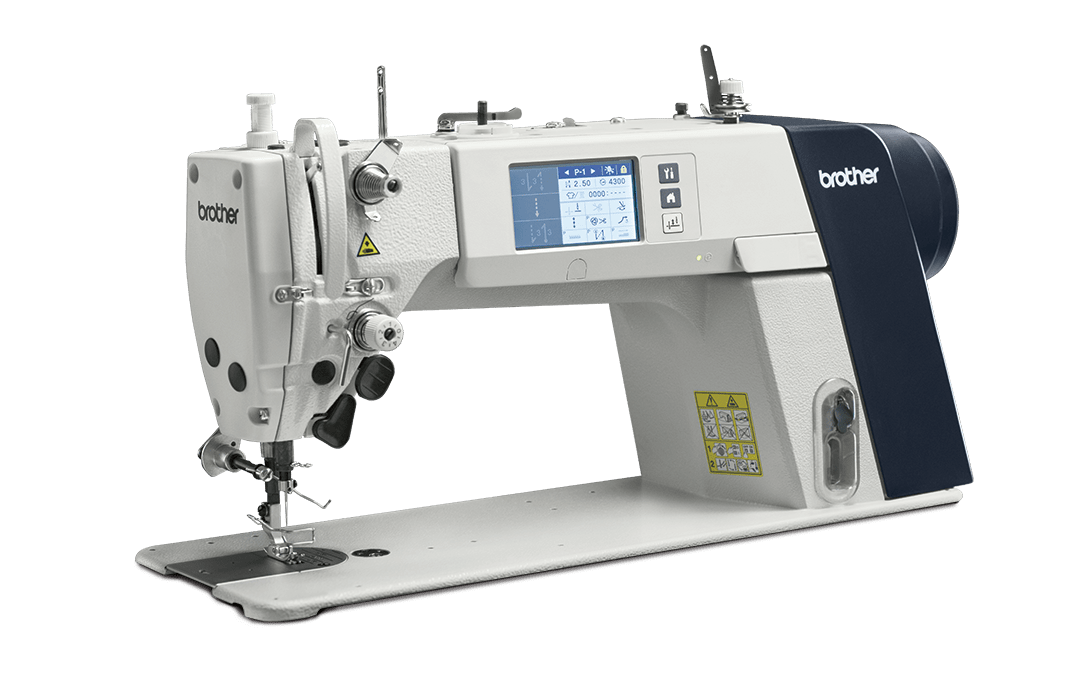

"We installed Brother IoT system in our new factory, 80 sewing lines equipped in 4 buildings."

PT Daehan Global is one of the largest woven vendors from Korea. They export their clothing to especially the US, which is GAP, Abercrombie, Wallmart, GUESS, and so on.

“DHG Brebes has 80 sewing lines equipped in 4 buildings. We are currently expanding the factory and at this time, we installed Brother IoT, NEXIO SYSTEM in our new factory.”

"Every day I usually start by checking the status of the sewing machines with the IoT system."

Ms. Widya Musyarofah, a staff of production planning described her satisfaction with the system. It has become an integral part of her daily work.

"After making sure the machines are turned on, I monitor the bar graph to check the output data on each machine and also the machine’s production progress."

For example, if there is a process where the sewing machine is turned on but the output data is not displayed on the graph, we go to the line to check the situation.Then I make the report based on the data result and send it to General Manager, Production Manager, and Production Chief.

"This system is a worthwhile investment."

It can be implemented in the latest sewing machines. Mr. Kim mentioned that they appreciate the system performance.

It can be implemented in the latest sewing machines. Mr. Kim mentioned that they appreciate the system performance.

![[Arvind in India] Single needle lockstitch sewing machine S-7300A](https://industrialsewingmachine.global.brother/-/media/ap2/ism/bma/customervoice/mayhai/img/img-mayhai-main.jpg?h=516&iar=0&w=1260&rev=-1)

![[Panwin in Bangladesh] Single needle lockstitch sewing machine S-7250A](https://industrialsewingmachine.global.brother/-/media/ap2/ism/bma/customervoice/daehan/img/img-daehan-main.jpg?h=517&iar=0&w=1260&rev=-1)