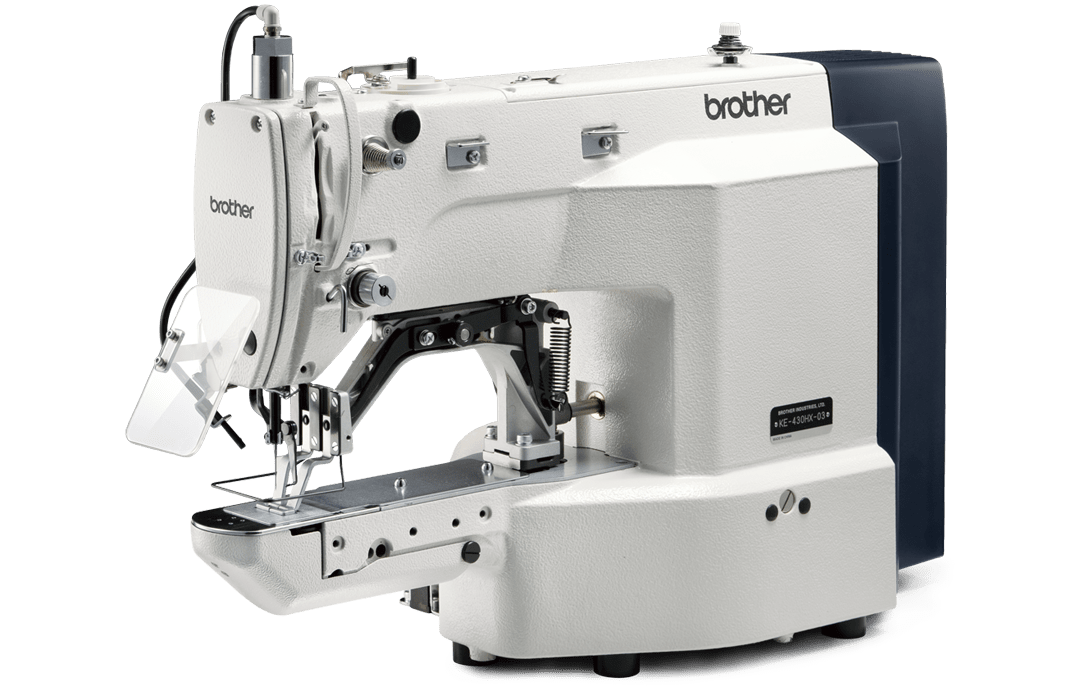

Customer review from Kay Tent in India on KE-430HX

Company Overview

Explore more information about the companyFactory Name

Kay Tent Industries

Interviewee

Mr. H.S. Sethi Director

Mr. Gauri Shankar Production in charge

Place

New Delhi, India

Number of Employees

200

Establishment Date

1967

Sewing Products

Tents, Rucksacks, Bags for executive and school

Relief items for disaster like blankets, tarpaulins

Manufacture for both domestic and export

Interview

“Needle cooling bartack has increased the revenue by 30% higher productivity.”

Kay Tent Industries have 100 years history and produce tents, rucksacks, and their own brand bags for school kids and executives.

The relationship with Kay Tent and Brother has been continued for 20 years. “Brother is very helpful in providing a solution to our typical needs.” Mr. H. S. Sethi, Director of Kay Tent explained why they selected Brother as a business partner. “Brother has a very good support system and very lass breakdowns of the machines. ”

They have purchased a lot of machines from Brother and recently added needle cooling bartack machines, KE-430HX. Mr. Sethi was telling the results: “This product is very useful for our heavy fabric application. We use it on 200gsm nylon fabric to craft the 70-liter rucksack. Since the thread is nylon, we faced a lot of problems in the thread breakages. But with this machine with the needle cooling application, we don’t face any such problems now.”

“Speed, quality, accuracy, durability is perfect.”

Mr. Gaurl Shankar, Production in charge continued, “We use to run bartack machines at less than 2,000 RPM because if we go above it, we did not achieve the desired quality and got a lot of troubles. But with KE-430HX, we can work at over 3,200 RPM with perfect accuracy and no thread breakages.”

“We have increased our revenue because now we can do the bartack 30% higher than what we were doing earlier.” Mr. Sethi smiled, “Bartack is very crucial on our various bags because we need to provide additional strength on some particular parts which are load-bearing parts of the equipment. By using this KE-430HX, we have achieved a different level of speed thanks to the superior needle cooling system.”

“Superior to other bartack machines”

As compared with other brand’s sewing machines, they are satisfied with Brother’s bartack. “By this machine, we have achieved lots of things which could not do with other brands and other products. the bartack has lots of advantages which increase our capacity from 2,000 RPM to 3,300 RPM. Obviously its needle cooler is, and it can expand the width of bartack and make a box too. It gives us accurate bartack and makes bigger boxed too. ” Mr. Sethi disclosed their pleasant feeling about the bartack.

“Everyone loves KE-430HX with less troubles.”

“The operators are very happy using this machine because they face less troubles of changing and putting the thread in needle all the time and their productivity is very high now. So even they are happy and the company is happy with them,” He said doubtlessly

“Also, this bartack machine does not require so much maintenance, so the mechanic role is very less with this machine.”

Director, production manager, operator, and mechanic, everyone appreciates KE-430HX in their factory.

“The best investment ever!”

“The investment in all the Brother sewing machines that we have made till date was a very wise decision because no machine gave us any troubles. Be it maintenance, be it productivity, be it speed, whatever we can think of can improve our production in the industry.” He kept smiling, “We can compete with the competitors and give a better product to the market and makes more profit for ourselves with Brother.” He concluded.

![[CKDL in Bangladesh] Bar tack sewing machine KE-430HX](https://industrialsewingmachine.global.brother/-/media/ap2/ism/bma/customervoice/img/img-voice-list-13.jpg?h=317&iar=0&w=500&rev=-1)