T-8722C

T-8722C

- ・Stable thread trimmer operation and large hook provide high productivity.

- ・Clean sewing with no oil staining

Information

Overview

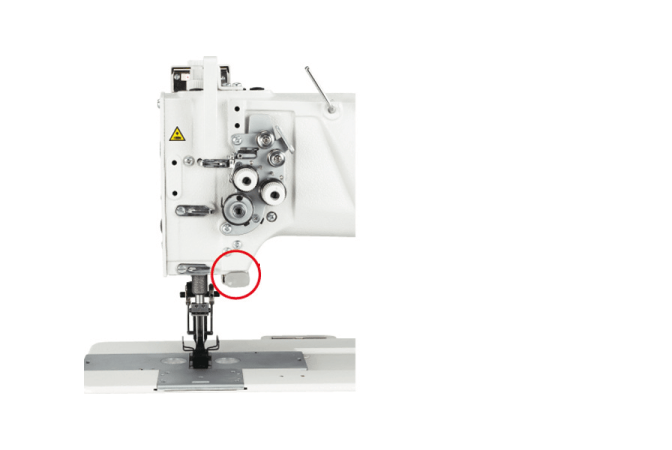

Great Needle Penetration Force

Powerful 550W motor outputs large amounts of torque even at slow speeds so that strong needle penetration force can be obtained. This allows accurate sewing of heavy materials and joints. If the needle penetration resistance increases, such as when sewing heavy materials and materials with joints, vibration control (intermittent impact) automatically increases the penetration force.(Patent pending)

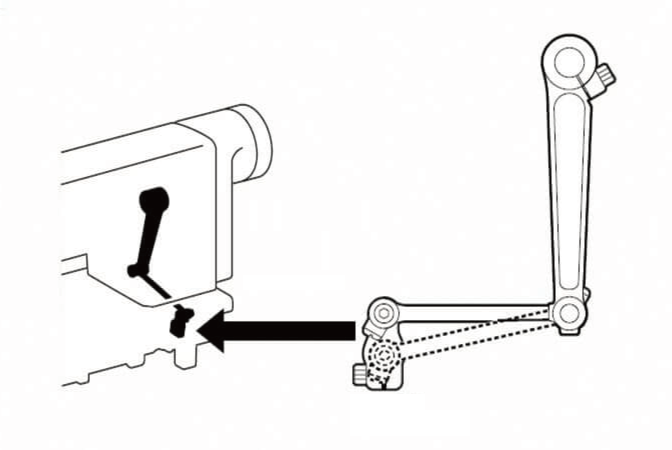

Feed Method Can Be Switched To Suit The Sewing Application

A function to switch between needle feed and lower feed is equipped as a standard function. Needle feed is effective in preventing uneven material feeding, and lower feed prevents puckering and is ideal for making quick and frequent turns. The operator can select the optimum feed method according to the material and the process, so that sewing quality can be increased.

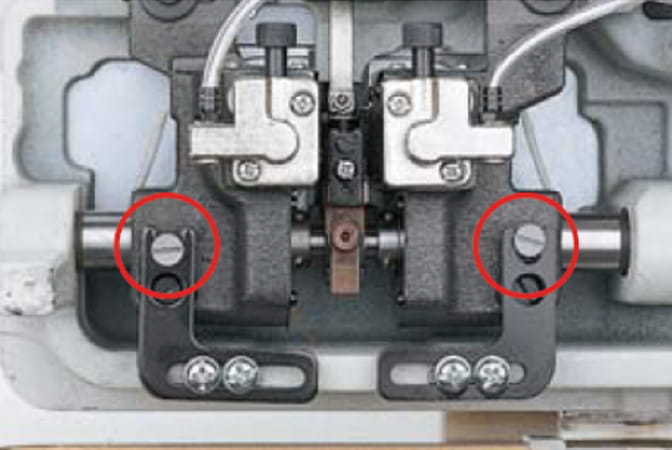

Easy Gauge Part Replacement

Cam adopted in the lateral position adjustment mechanism for the rotary hook base allows easy fine adjustments for clearance between needle and rotary hook point can easily be made, which greatly increases the efficiency of replacing gauge parts. Furthermore, a needle drop correction function (sideways) is provided, so that the needle drop position can still be adjusted to the center of the needle hole even if using commercially-available gauge parts. The gauge parts for previous models can still be used without any changes.

Features

Specifications

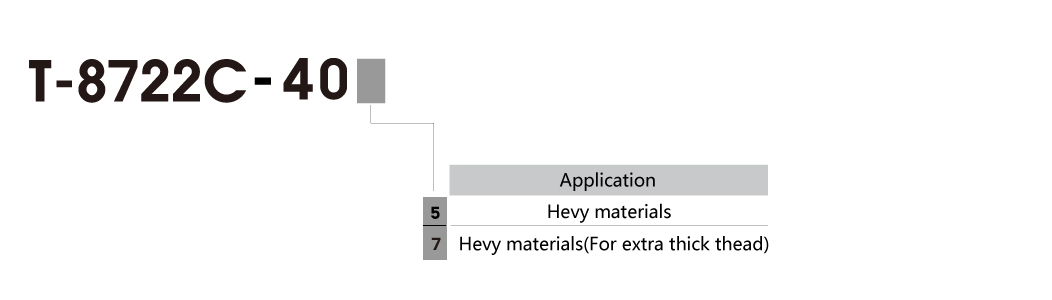

| T-8722C | -405 | -407 |

|---|---|---|

| Lubrication type | Minimum lubrication | |

| Application | Heavy materials | |

| Max. sewing speed | 3,000 sti/min | |

| Needle | DPx5

(#22) |

|

| Max. stitch length | 7.0mm | |

| Presser foot height | 7.0mm | |

| Start backtacking and continuous backtacking speed | 250〜1,800sti/min | |

| End backtacking speed | 1,000sti/min | |

| Height of feed dog | 1.0mm | |

| Weight | Machine head : 49.5kg

Control box : 3.1kg |

|

| Arm pocket size | 120 .0mm x 264.0mm | |

| Arm bed size | 517.5mm x 178.0mm | |

| Bobbin winder | Included in machine arm | |

| Machine head drive | Direct drive mechanism | |

| Motor |

(4-pole,550W) |

|

| Control circuit | Microprocessor | |

| Power | Single-phase : 100V

3-phase : 200V 400VA |

|