T-8750C

T-8750C

- ・High position of arm jaw and large arm pocket make handling material easier.

- ・Easy to replace gauge parts.

Information

Overview

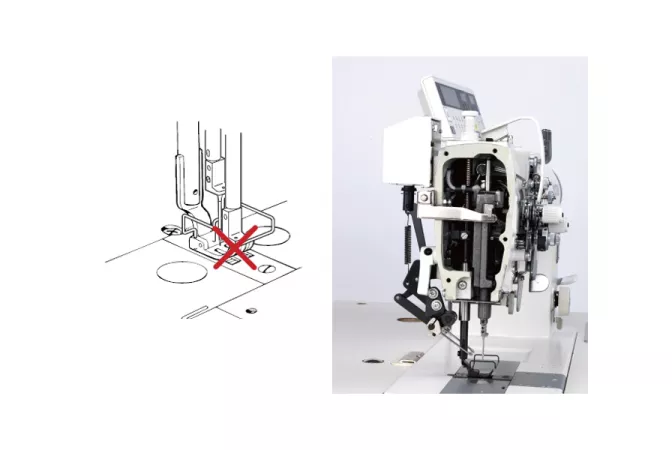

All Possible Measures To Prevent The Needle Bar From Falling Out Have Been Taken Avoid Damages To The Sewing Machine

If you accidentally touch the stop lever (selection lever) during high speed sewing, you do not have to worry. The sewing machine is equipped with the safety mechanism which prevents the needle bar from falling out.

Sufficient consideration for safety of sewing operation is given so that fatal damage to the sewing machine will be avoided.(Patent pending)

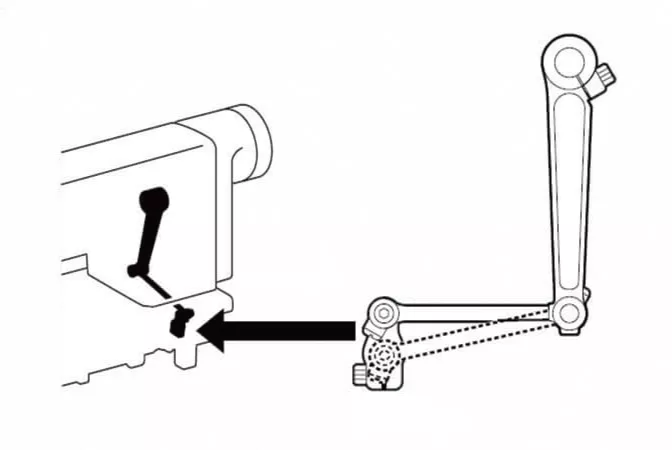

Quick Needle Bar Select Function Reduces Operator Fatigue

One of the needle bars can be stopped simply by changing the position of the stop lever (select lever). Compared to the previous models, a stroke of the stop lever has been shortened to optimum stroke and the weight of the lever has also been reduced by about 10 % so that easy operation is possible with a light touch of the lever.

The setting can be returned to twin needle sewing simply by pushing the push lever plate. The push lever plate can be removed from the front face of the sewing machine and easily replaced so that it can be adjusted to the best position.

In addition, with the adoption of center stop mechanism, the stop lever automatically and accurately returns to the center position to prevent setting errors when it is set back to the twin needle sewing.

Feed Method Can Be Switched To Suit The Sewing Application

A function to switch between needle feed and lower feed is equipped as a standard function. Needle feed is effective in preventing uneven material feeding, and lower feed prevents puckering and is ideal for making quick and frequent turns. The operator can select the optimum feed method according to the material and the process, so that sewing quality can be increased.

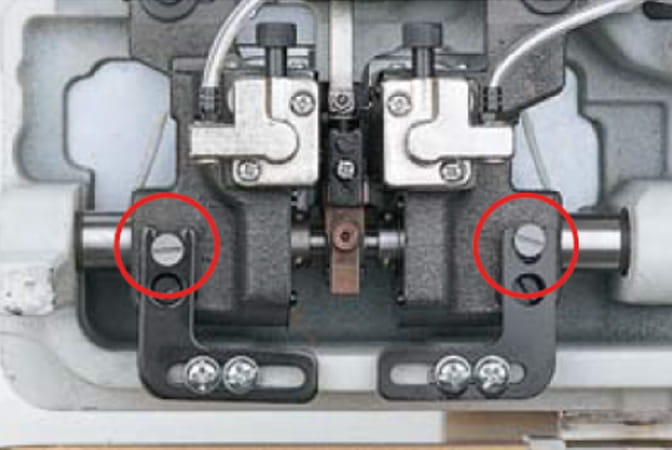

Easy Gauge Part Replacement

Cam adopted in the lateral position adjustment mechanism for the rotary hook base allows easy fine adjustments for clearance between needle and rotary hook point can easily be made, which greatly increases the efficiency of replacing gauge parts. Furthermore, a needle drop correction function (sideways) is provided, so that the needle drop position can still be adjusted to the center of the needle hole even if using commercially-available gauge parts. The gauge parts for previous models can still be used without any changes.

Features

Specifications

| T-8750C | -005 |

|---|---|

| Lubrication type | Minimum lubrication |

| Application | Heavy materials |

| Max. sewing speed | 3,000sti/min |

| Needle | DPx5

(#22) |

| Max. stitch length | 7.0mm |

| Presser foot height | 7.0mm |

| Height of feed dog | 1.0mm |

| Weight | Machine head : 43.0kg |

| Arm pocket size | 120.0mm x 264.0mm |

| Arm bed size | 517.5mm x 178.0mm |

| Bobbin winder | Included in machine arm |

| Machine head drive | Belt drive mechanism |

| Power | Single-phase : 100V

3-phase : 200V 400VA |