NEXIO BAS-365H

NEXIO BAS-365H

- Bridge Type Programmable Electronic Pattern Sewer

- ・Bridge type mechanism provides great sewing quality at higher sewing speeds

- ・World’s top-class productivity and sewing quality with Great sewing speeds(Max. 2,700sti/min)

- ・User-friendly Color LCD with Touch Panel Display

- ・A needle cooler preventing thread breakage thus for greater sewing speeds

- ・For Use with Various Types of Sewing Applications ・Max. sewing area: 700mmx400mm

Catalog, Manual, Parts-book Download

Information

Overview

The large sewing area provides greater flexibility

The large sewing area enables the setting of multiple workpieces of such as shoes or bags at the same time and to sew larger applications such as automotive airbags, providing enhanced productivity.

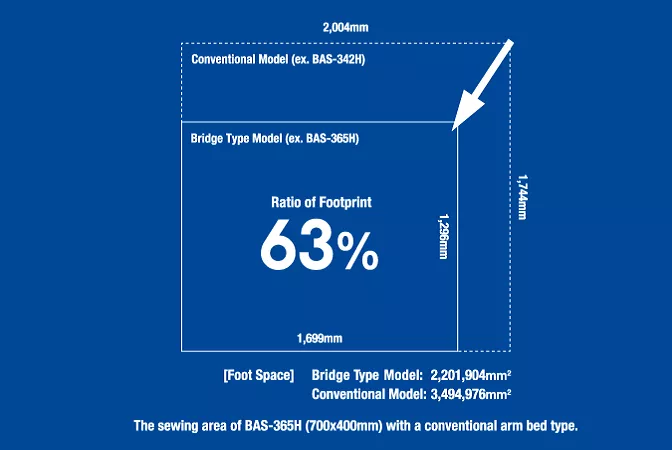

Effective utilization of factory floor space with compact footprint

The workspace footprint is extremely small for the larger sewing area provided when compared to a conventional type BAS machines *1, allows making additional space for another machine.

*1 Programmable electronic sewing machine with sewing area larger than or equal to 200,000m㎡

Productivity improvement by IoT

Brother NEXIO series are IoT applicable models*2. Connecting sewing machine to a network enables customers to analyze, manage processes, improve productivity, and monitor required maintenance. *2 It is applicable for Brother’s IoT system. For more details, please refer to the catalog of “Brother Industrial Sewing Machine Network System”.

Features

Specifications

| BAS-365H | |

|---|---|

| Stitch form | Single needle lock stitch |

| Max. sewing speed | 2,700sti/min (R spec: 2,200sti/min) |

| Max. sewing area | 700x400mm |

| Footprint | 1,699mmx1,296mm |

| Feed mechanism | Intermittent feed (pulse motor drive) |

| Stitch length | 0.05-20.0mm (per 0.05mm) |

| Max. number of stitches | 100,000 stitches (per program) |

| Max. number of programs | 999 |

| Work clamp lift amount | Max. 52.5mm |

| Height of stepping presser foot | 25mm(highest needle stop position) |

| Stepping presser foot stroke | 0-10mm(per 0.1 mm) |

| Work clamp | Pneumatic work clamp |

| Head lifting function | - |

| Head lifetable | - |

| Needle cooler | Standard equipment |

| Thread wiper | Standard equipment |

| Thread trimmer | Standard equipment |

| Digital tension | Standard equipment |

| Thread breakage detector | Standard equipment (fiber sensor drive) |

| Data storage media | Internal flash memory (data addition is available with external memory) |

| Motor | AC servo motor 550W |

| Weight | Approx. 640kg |

| Power | Single phase 200V / 220V 3-phase 200V -240V |

| Apparent power/Power consumption | 1000VA/ 590Wh |

| Air pressure/Consumption | 0.5MPa/Needle cooler ON:8l/min OFF:0.2/min |