NEXIO BAS-370K

NEXIO BAS-370K

- ・Bridge Type Programmable Electronic Pattern Sewer.

- ・Minimizing downtime with digital sensing technology Wide sewing area for large items.

- ・Equipped with the DIGIFLEX TUNE feature, which digitizes analog adjustments.

- ・Skipped stitches detection, thread breakage detection, dynamic upper thread tension monitoring.

- ・XY independent feed mechanism is Achieving high-quality sewing.

- ・Max. sewing area: 800mmx700mm (800mm×850mm)*1 *1 By changing the settings, movement of 850mm is possible.

Catalog

Information

Overview

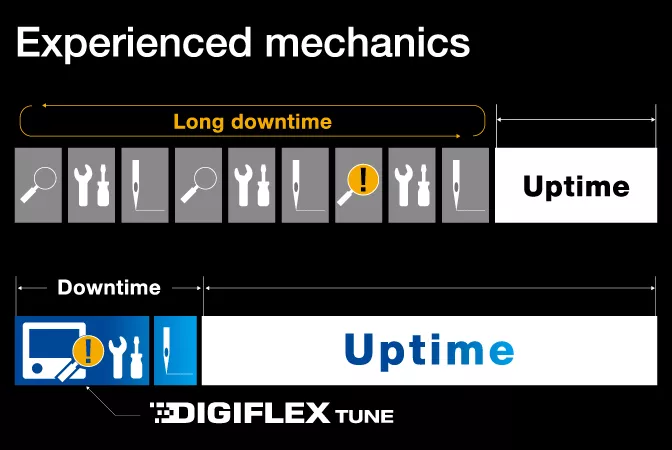

Sensing makes it clear how to handle sewing defects, minimizes downtime and increases productivity.

The adjustment time of the sewing machine due to poor sewing is greatly reduced by sensing technology.The cause of the sewing defect can be identified and appropriate adjustments can be made just from the numerical values on the panel.

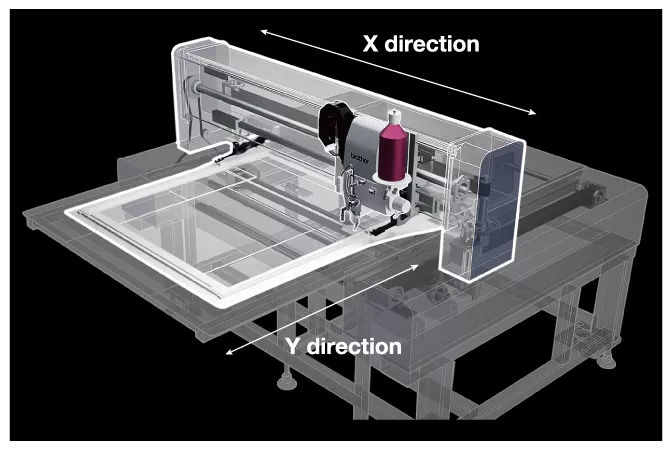

XY independent feed mechanism is Achieving high-quality sewing.

By maximizing the sewing area through the adoption of bridge-type mechanism, it is now possible to sew large pieces of material such as airbags, which were previously difficult to sew. In addition, the XY independent feed mechanism achieves high sewing accuracy, making it possible to perform high-quality "design stitches" on car seats, leather products, etc.

Upper thread tension monitoring is skipped stitches detection, thread breakage detection, dynamic upper thread tension monitoring.

By detecting sewing defects by detecting skipped stitch, thread breakage detection, and dynamic upper thread tension monitoring, defective products are prevented from flowing to the downstream process. By directly detecting the upper thread tension with a magnetic sensor, it is possible to distinguish between skipped stitch and thread breakage. *As we continue to monitor upper thread tension, we plan to add other criteria for defects and abnormalities.

*2 It is applicable for Brother’s IoT system. For more details, please refer to the catalog of “Brother Industrial Sewing Machine Network System”.

Features

Direct Roll Sewing System

By sewing the raw material directly before cutting, it is possible to customize the before and after processes, such as the roll-to-roll method.

XY axis independent drive mechanism

By maximizing the sewing area through the adoption of bridge-type mechanism, it is now possible to sew large pieces of material such as airbags, which were previously difficult to sew. In addition, the XY independent feed mechanism achieves high sewing accuracy, making it possible to perform high-quality "design stitches" on car seats, leather products, etc.

Intermittent stepping presser foot by pulse motor

Intermittent stepping presser foot is independently driven using a pulse motor. By sewing with the stepping presser foot lowered at the beginning of sewing, it is possible to reduce prevent skipped stitches at sewing start. In addition, stroke adjustment can be done only by operating the panel, and it is easy to operate by simply setting the stroke amount after setting the lowest point of the intermittent stepping presser foot as the reference.

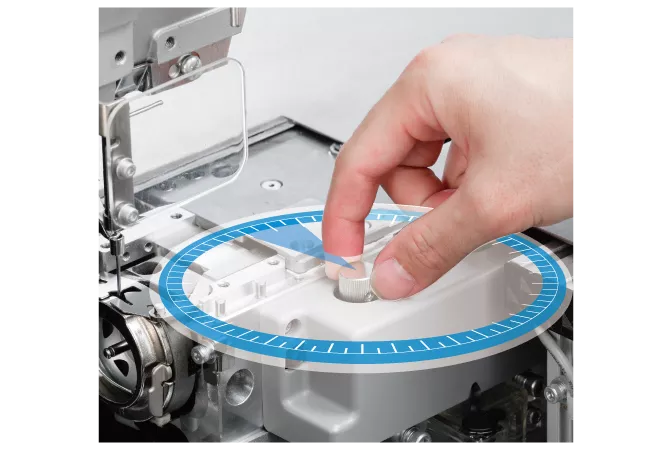

Easy adjustment

The shuttle hook area maintenance cover (with open/close sensor) has been enlarged. The work surface height has been reduced 50mm improving accessibility and making adjustments easier.

By maximizing the sewing area through the adoption of bridge-type mechanism, it is now possible to sew large pieces of material such as airbags, which were previously difficult to sew. In addition, the XY independent feed mechanism achieves high sewing accuracy, making it possible to perform high-quality "design stitches" on car seats, leather products, etc.

Specifications

| BAS-370K | |

|---|---|

| Stitch form | Single needle lock stitch |

| Hook | Double-capacity shuttle hook |

| Max. sewing speed | 2,500sti/min |

| Max. sewing area(W×D) | 800mm×700mm (800mm×850mm)* ※By changing the settings, movement of 850mm is possible. |

| Footprint(W×D×H) | 1,800mm×2,080mm×1,719mm |

| Feed mechanism | Intermittent feed (pulse motor drive) |

| Stitch length | 0.05~20.0mm (per 0.05mm) |

| Max. number of stitches | 100,000 stitches (per program) |

| Max. number of programs | 999 |

| Height of stepping presser foot | 28mm (highest needle stop position) |

| Intermittent presser foot stroke | 0-10mm(per 0.1 mm) |

| Machine head lifter | Standard equipment |

| Machine head lift amount | 70mm (height from the top of the auxiliary plate Max.95mm) |

| Needle cooler | Standard equipment |

| Thread wiper | Standard equipment |

| Thread trimmer | Standard equipment (pulse motor drive) |

| Digital tension | Standard equipment |

| Material thickness detection function | Intermittent presser foot pulse motor type |

| Upper thread tension sensor | Skipped stitches detection,thread breakage detection,Dynamic upper thread tension monitoring (Dynamic tension detection method) |

| Upper thread slip prevention function | Standard equipment (by Intermittent presser foot) |

| Lower thread gripping mechanism | Standard equipment |

| Needle bar position monitoring | Standard equipment |

| Needle guard monitoring | Standard equipment |

| Meeting timing monitoring | Standard equipment |

| Needle gap monitoring | Standard equipment |

| Oil level monitoring | Standard equipment |

| Data storage media | Internal flash memory (data addition is availabe with external memory) |

| Weight | Approx. 900㎏ |

| Power | Single phase 200V、 220V 3-phase 200V-240V /1200VA |

| Air pressure/Consumption | 0.5MPa /Needle cooler ON: 8l/min OFF: 0.2l/min |