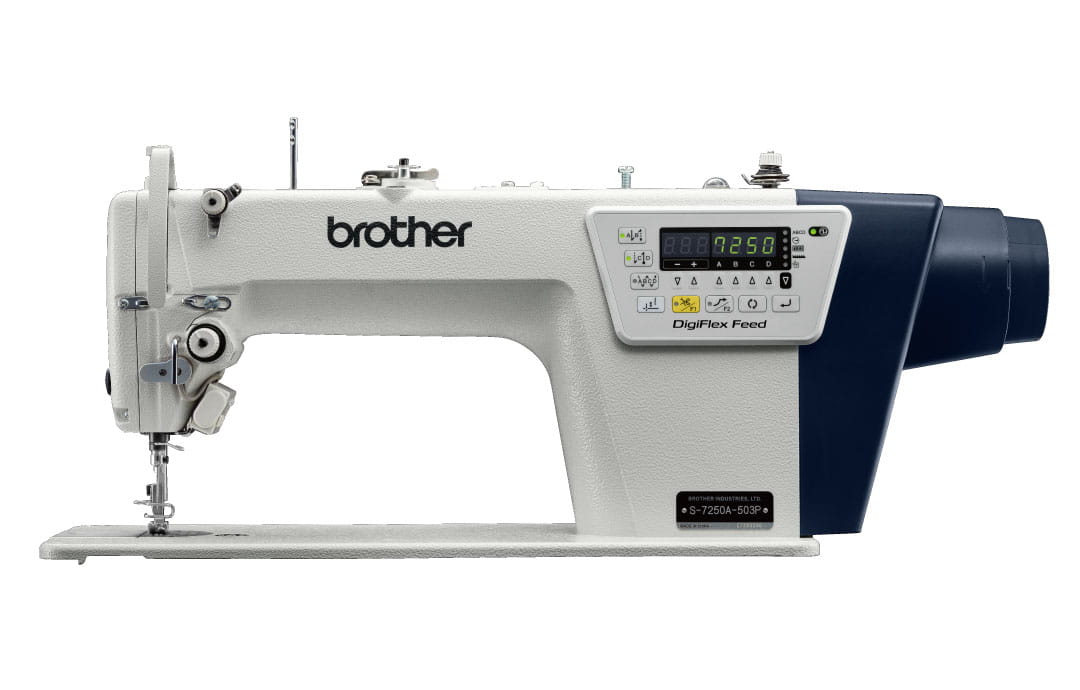

NEXIO S-7250A

NEXIO S-7250A

- Single Needle Direct Drive Lock Stitcher with Electronic Feeding System and Thread Trimmer

- ・Reduces needle breakage, puckering and materials slippage with DFF

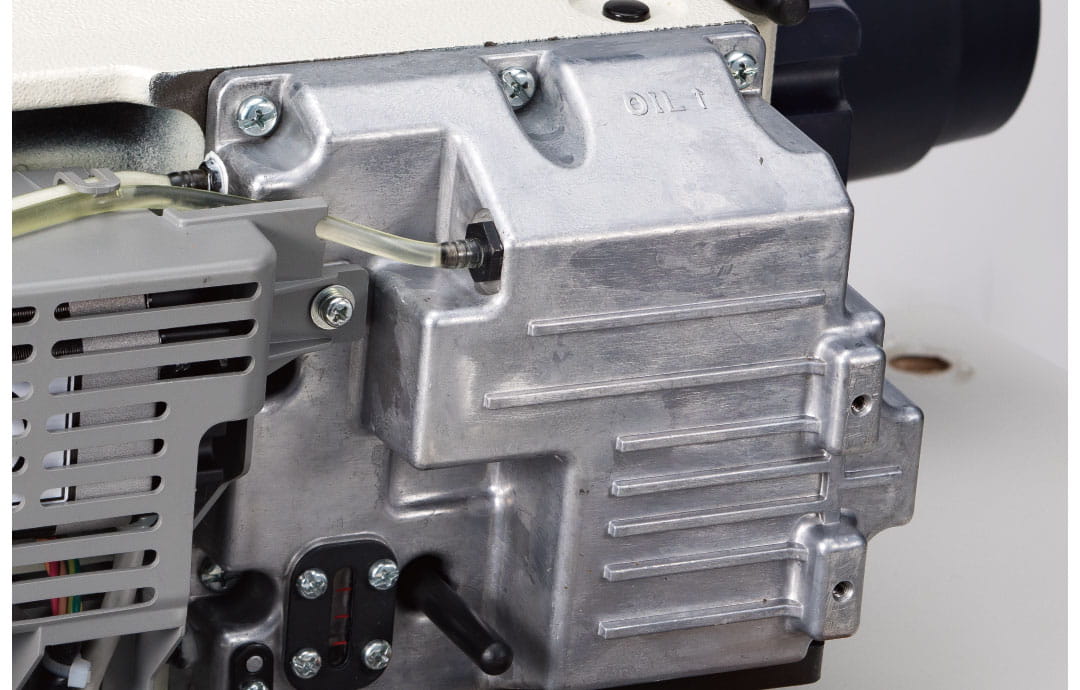

- ・Elimination of oil stains due to the adaption of the sealed type oil pan.

- ・Productivity improvement management by utilizing loT

Catalog, Manual, Parts-book Download

Information

Overview

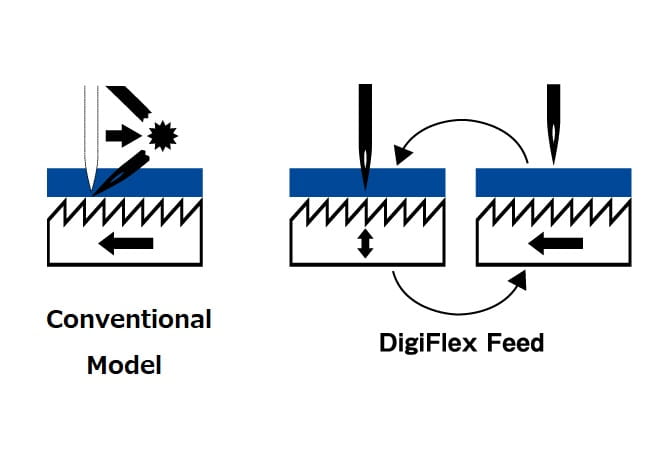

Change from mechanical control to stepping motor control by equipped DFF

Compared to conventional mechanical control, the stepping motor control makes the response of reverse sewing quicker and reduces needle breakage.

Equipped with needle prevent breakage function while reverse sewing

Sensing needle position and controlling proper feed timing that prevent from unreasonable reverse sewing as needle breaks automatically.

Features

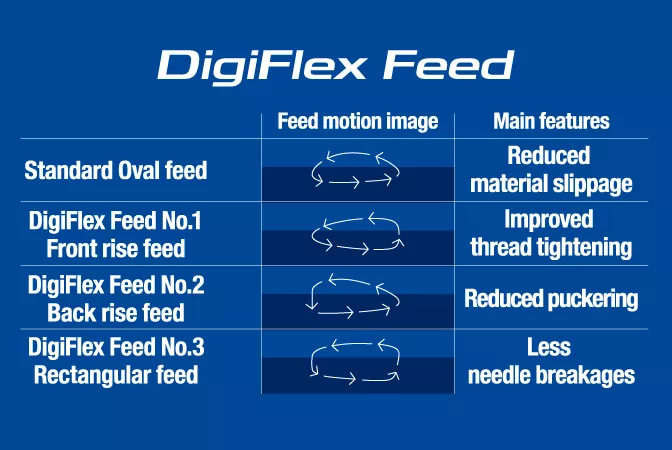

DigiFlex Feed, which is world's first equipped on S-7300A and highly evaluated in the

market,

digitalizes feeding system and resolves various sewing troubles without adjustment work.

- Improvement in the reduction of needle breakage and productivity.

- Simple select and smooth sewing without material slippage.

- Excellent sewing quality that's easy to get proper thread tension in accordance with several materials

Optimization of fabric feed timing by changing feed motion of DigiFlex Feed

Fabric can be feed at an appropriate timing so that needle won't break even during thick material sewing.

Change from mechanical control to stepping motor control by equipped DigiFlex Feed

Compared to conventional mechanical control, the stepping motor control makes the response of reverse sewing quicker and reduces needle breakage.

Equipped with needle prevent breakage function while reverse sewing

Sensing needle position and controlling proper feed timing that prevent from unreasonable reverse sewing as needle breaks automatically.

Short remaining thread by 3mm doesn't require after-cutting process

Minimizes the bird's nest at sewing start and short remaining thread min. 3mm.

The new double action thread trimming mechanism cuts the thread right under the needle hole, realizing the short remaining thread.

The disposition of thread ends after sewing can be reduced thanks to the new system. (Premier Spec.)

You can change the stitch length and sewing speed easily. In addition,

it is possible to set the stitch length as a numerical value, and the reproducibility of sewing is improved.

Specifications

.jpg?rev=85b32744345341248e62283607c714f5)

| S-7250A | -503 | -505 | -503P | -505P |

|---|---|---|---|---|

| Lubrication type | Minimum lubrication | Minimum lubrication | ||

| Application | Medium materials | Heavy materials | Medium materials | Heavy materials |

| Max. sewing speed | 5,000 sti/min(*1) *1:Stitch length 2.0mm and under. |

4,000 sti/min | 5,000 sti/min(*1) *1:Stitch length 2.0mm and under. |

4,000 sti/min |

| Max. bac tacking speed | 3,000 sti/min | 3,000 sti/min | ||

| Max. stitch length | 5mm | Max.7mm (default setting:5mm) |

5mm | Max.7mm (default setting:5mm) |

| Thread trimming mechanism | Single action trimming mechanism (Ordinary type) | Double action trimming mechanism | ||

| Presser foot height | Presser bar lifter:6mm, Knee lifter: 13mm | |||

| Needle bar stroke | 31mm | 35mm | 31mm | 35mm |

| Needle (DBX1 ・DPX5) | #11-#18 (Nm75-110) |

#19-#22 (Nm120-140) |

#11-#18 (Nm75-110) |

#19-#22 (Nm120-140) |

| Height of feed dog | 0.8mm | 1.2mm | 0.8mm | 1.2mm |

| Weight | 35kg | |||

| Motor | AC servo motor | AC servo motor | ||

| Power | 100-110V(*2),200V-230V,380V-400V(*2)under450VA *2: The transformer is required. |

|||