Data Trend from NEXIO SYSTEM - Jul, 2020

Try Brother's NEW SERVICE for work efficiency improvement FOR FREE!

We are now offering a free service where our specialist will prepare a report

specifically for your factory and explain where to improve.

In the wake of the global economic crisis, Brother helps customers who want to

review your own production situation to improve work efficiency.

After you sign up, you will be contacted by a representative to clear up any

questions and schedule a consultation, so feel free to sign up first and ask about your

concerns.

3 tips to increase productivity in small-lot production

Short-term productivity improvements by 5% learned from Vietnam's largest factory

Today, on the theme of improving factory productivity, we would like to introduce

a major factory in Vietnam that succeeded in increasing productivity by 5% with

small-lot production.

Many factories are probably engaged in Time-study to improve productivity. Typically,

two to three times Time-study is conducted for each style change for productivity

improvement, but in small-lot production, which sewing around 700

pieces per day and be completed within three days, many factories may have given

up on making improvements.

The reason is that Time-study takes more than two hours per line, and including the

time for data analysis, production would be completed before any improvements

are made.

IE and line leaders have faced problems.

That factory in Vietnam, like the others, had given up on improving short-run

production.

It would take too long to measure each operator's work with a

stopwatch, and it also would take a lot of effort to compile and

analyze the data after the measurement.

In addition, line managers were faced with the problem of discrepancies between

the measurement results and the operators' self-awareness, which prevented

them from finding bottlenecks and making improvements.

3 key points for small-lot production improvement

There are three things that are necessary to improve small-lot production.

(1) Fast and accurate measurement

(2) Rapid reporting

(3) Data sharing among stakeholders

This factory made it possible with the NEXIO SYSTEM.

Finally, they succeeded to increase productivity by 5%!

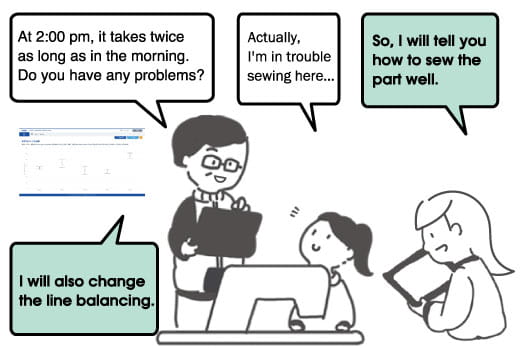

The data is collected directly from the sewing machine and automatically

graphed.

This eliminates the need for manual time measurement and allows the user to

quickly check the automatically graphed data.

With IE, line managers, and operators being able to see the same data, and

disagreements have been eliminated.

Operators are more open and honest in explaining their issues to the cause of the

drop in production, and line managers are more willing to give appropriate

feedback.

Now, in the short-run & small-lot production, they were able to increase

productivity by a whopping 5%.

"It has all the features managers ask for", Director says of the NEXIO System, "It's

a great way to increase our efficiency and give our company a competitive edge."

What is the bottleneck in your factory's case?

You can find out with Brother's 1-Line Assessment. Sign up today to be entitled to close the offer!