Data Trend from NEXIO SYSTEM - Jul, 2020

Is Large Investment Necessary for Improvement?

Against COVIT-19, many factories are forced to enhance work efficiency. However, isn't

it difficult to find where to/how to improve without any proper suggestion from

professional?

- RFID burdens on sewing operator by extra tasks and requires time and high effort

to educate them to input data constantly.

- Grasping line bottleneck data automatically or quick way requires system but most

of them are complicated and expensive.

- It’s difficult to judge which automation products or devices are suitable for our

production line.

etc.

Budget and effort are necessary. Is it correct?

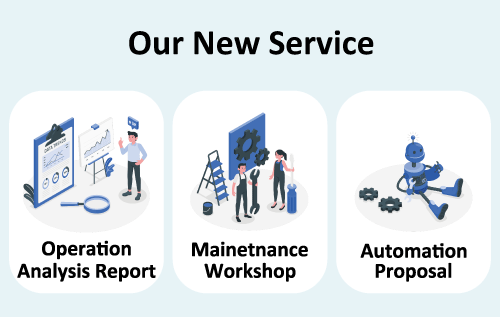

Brother is now providing 1 Line Assessment including 3 types of services!

In order to improve work efficiency, Brother is offering new 3 services.

| Operation Analysis Report | ・Line data visualization

・Check real productivity ・Find where to improve |

|---|---|

| Maintenance Workshop | ・Technical Q&A

・Machine adjustment ・How to utilize machine |

| Automation Proposal | ・Factory survey

・Find where to automate ・Propose automation |

Operation Analysis Report

Our IE specialist will check productivity of 1 line in your factory and give a report

with line data visualization to show where to improve.

Quick survey

It will be completed in a few hours by just attaching a communication module into

your machines.

Reliable data

Data will be collected automatically from sewing machines without human

intervention. No need for operator’s extra work nor inaccurate measurement by a man.

Detailed report

Line balancing, cycle time, operation ratio, operator stability, and you can also

find out the rank of your operators compared to others in Asia based on more than

300,0000 sewing machines data.

Maintenance Workshop

Our technical team will offer your team a following activities. If you have any troubles

in your machines, use this opportunity well

Brother’s technical specialists help you with

- Technical Q&A

- Machine Adjustment

- How to utilize machine

Automation Proposal

Brother‘s automation team will visit production line and will find process which can be

automized and save labor cost with simple automation.

Brother customized devices

- Label attaching

- Expansion kit

- Bridge type BAS-H series

IMB products

- Shirts automation

- Trouser automation

- Button feeder

etc.

SPECIAL OFFER against COVID-19 - FREE!

Now, we are offering these services for FREE to overcome this difficult

time.

Brother is always at your side. Let's expand business together!

Sign up today and find out machine utilization!

Our specialist will contact you once you have applied. We will

explain the details of IoT system and answer your questions.

Then, schedule a visit to your factory accordingly. Please do not hesitate to contact

us.

Please read

the Terms of Use here and send the application if you agree to it.