KE-430FX II

KE-430FX II

- ・Reduction of Disposition of Thread Ends and Enhanced Sewing Capability can Improve the Quality

- ・Overwhelmingly superior productivity with the world's top-class cycle time

- ・Digital tension as standard equipment

- ・User-friendly Operation Panel

- ・Clean Sewing with Semi-dry Type

Information

Overview

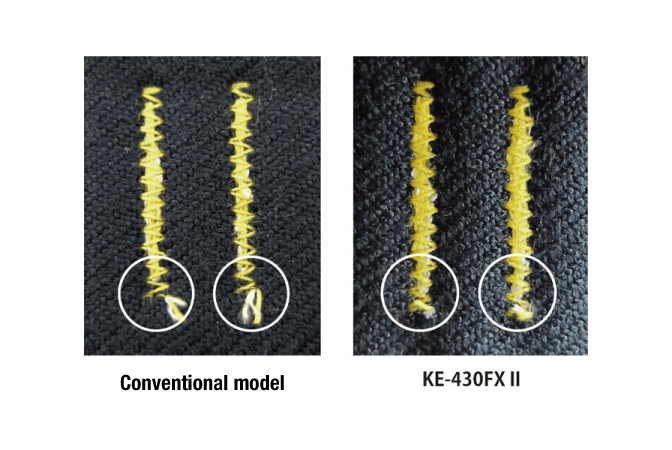

Reduction of Dispositon of Thread Ends (Short Remaining Thread)

Renewed thread trimmer cuts the thread, realizing short remaining threads. The disposition of thread ends after sewing can be redued. Also, the thread nipper, equipped as standard, minimizes thread cast off at sewing start and bird's nest.

Enhanced Sew-capability for Medium Materials

The brand new thread take-up stroke provides stable thread tightening. So that medium material specification covers heavy material usage.

Overwhelmingly superior productivity with the world's top-class cycle time

Since a direct drive system is used, the KE-430FX II boasts the world's top-class sewing speed 3,200 sti/min in shuttle hook sewing machines. Since the work clamp lift amount can be set in two steps, it contributes to enhanced productivity.

Features

Reduction of disposition of thread ends(short remaining thread)

Renewed thread trimmer cuts the thread, realizing short remaining threads. The disposition of thread ends after sewing can be reduced. Also, the thread nipper, equipped as standard*. minimizes thread cast off at sewing start and bird's nest.

Enhanced sew-capability for medium materials

The brand new thread take-up stroke provides stable thread tightening. So that medium material specification covers heavy usage.

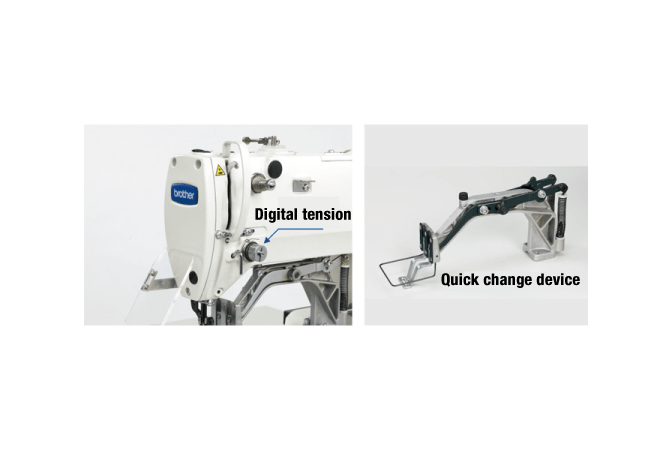

Digital Tension is equipped as standard so you can adjust the tension appropriately for the material being sewn. No more relying on individual feel, changing the thread tension can be added onto the sewing programs.

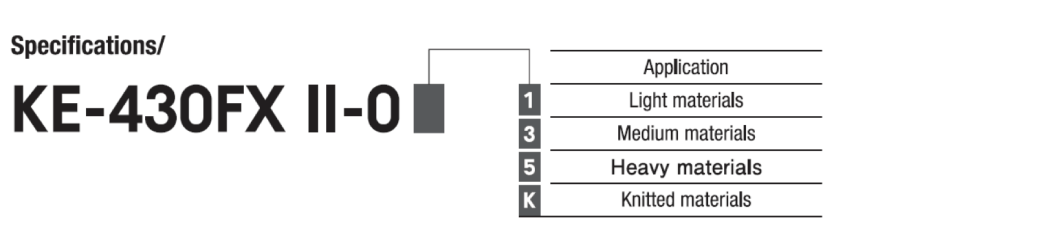

Specifications

| KE-430FX II | 1 | 3 | 5 | 0K |

|---|---|---|---|---|

| Application | Light materials | Medium materials | Heavy materials | Knitted materials |

| Lubrication | Semi-dry | |||

| Max. sewing speed | 3,200sti/min | |||

| Max. sewing area | Max. 40x30mm | |||

| Stitch length | 0.05~12.7mm | |||

| Feed mechanism | Y-θintermittent feed mechanism (pulse-motor driven mechanism) | |||

| No. of stitches | Variable (Refer to "Program List" for details on the number of stitches for sewing patterns that are already preset) | |||

| Max.No. of stitches | 5,000 stitches/pattern | |||

| Work clamp lifter | Pulse motor drive system | |||

| Work clamp height / Button clamp height | Max. 17mm | |||

| Rotary hook | Shuttle hook (double shuttle hook, optional) | |||

| Digital tension | Standard equipment | |||

| Thread wiper | Standard equipment | |||

| Thread trimmer | Standard equipment | |||

| Thread nipper | -01,-03,-0K: Standard equipment(-05: Option) | |||

| Data storage method | Flash memory (Any sewing pattern can be added using SD card) | |||

| Exteernal data storage method | SD card*1 | |||

| No. of cycle programs | 30 cycle (50 programs for each cycle) | |||

| No. of stored data | 89 sewing patterns are set already | |||

| (up to 512 patterns can be added. Total number of stitches of stored data which can be added is within 500,000*2) | ||||

| Motor | AC servo motor 550W (Direct Drive) | |||

| Weight | Machine head: Approx. 57kg, Operation panel: Approx. 0.4kg, Control box: Approx. 9kg | |||

| Power supply | Single-phase 100V/200V, 3 phase 220V/380V/400V 400VA (For single-phase 100V and 3-phase 380V/400V, the trans box is require | |||