NEXIO RH-982A

NEXIO RH-982A

- Electronic Eyelet Button Holer

- ・Reduce Adjustment Time

- ・Beautiful and High Quality Sewing

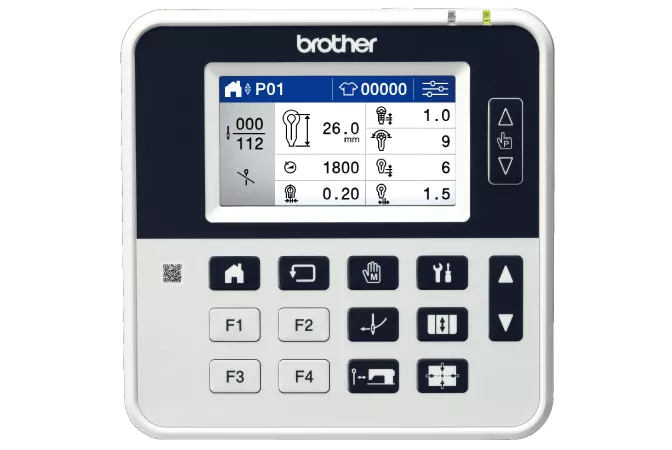

- ・User- intuitive Color LCD with Touch Panel

- ・Sewing Capability for A Wide Range Materials

Catalog, Manual, Parts-book Download

Information

Overview

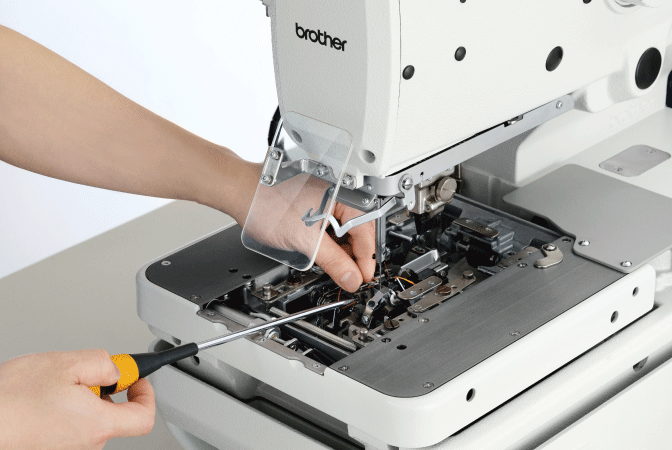

Reduce adjustment time

Since the sewing range is wide and there are few complicated adjustments peculiar to eyelet sewing machines, it contributes to the reduction of adjustment time. Achieves beautiful seams with simple adjustments. The durable electrical control design provides long lasting operation that greatly contributes to productivity performance.

Beautiful and high-quality sewing

The highly reliable sewing looper shape and needle guard shape reduces stitch skipping and thread tightening defects caused by changes in thread tension. With simple adjustments, you can achieve beautiful and sustainable sewing. It can also be used for items such as suits that require a high-end appearance and feel.

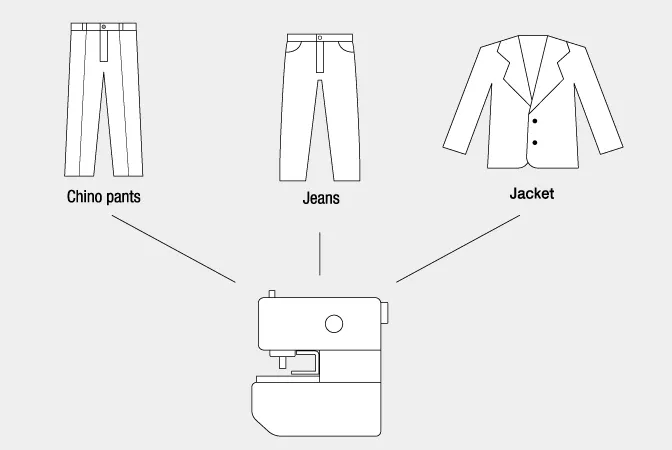

Sewing capability for a wide range materials

From thick fabrics for jeans to chino pants, suits, work clothes, and other thin fabrics, the brother eyelet button holer can handle a wide range of sewing materials. Equipped with an air cylinder type powerful and accurate hammer, it boasts outstanding stability even when cutting different materials. Overturning conventional wisdom, it is possible to consider using different materials with one model.

Features

Since the sewing range is wide and there are few complicated adjustments peculiar to eyelet sewing machines, it contributes to the reduction of adjustment time. Achieves beautiful seams with simple adjustments. The durable electrical control design provides long lasting operation that greatly contributes to productivity performance.

The highly reliable sewing looper shape and needle guard shape reduces stitch skipping and thread tightening defects caused by changes in thread tension. With simple adjustments, you can achieve beautiful and sustainable sewing. It can also be used for items such as suits that require a high-end appearance and feel.

From thick fabrics for jeans to chino pants, suits, work clothes, and other thin fabrics, the brother eyelet button holer can handle a wide range of sewing materials. Equipped with an air cylinder type powerful and accurate hammer, it boasts outstanding stability even when cutting different materials. Overturning conventional wisdom, it is possible to consider using different materials with one model.

The arm pocket of 120 mm depth gives a sufficient space, enabling Smooth setting of material. The arm shape provides a good view of the needle area, allowing operators to observe the sewing operation. It is the most suitable for sewing of vertical buttonholes and hip pocket parts. The newly equipped LED handy light is provided as standard and helps provide better viewing when placing fabrics or garments.

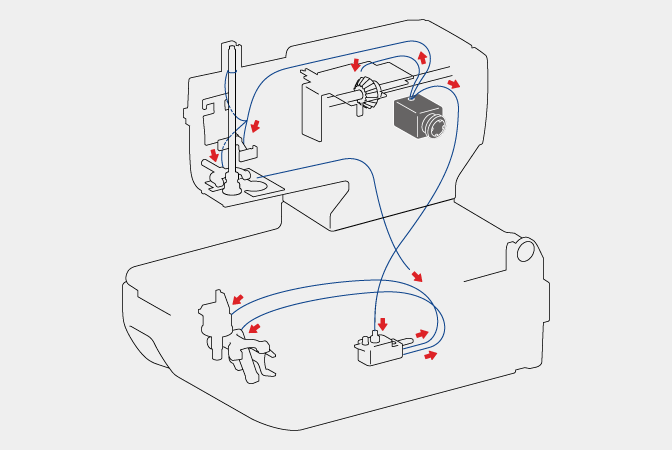

Centralized lubrication system

The location to supply oil have been concentrated into one. minimum oil is automatically lubricated with wicks from the oil tank to every part requiring lubrication, such as the areas of the needle bar and looper base. the oil level window is laid out at the position easy check.

Specifications

| Specifications | -00 | -01 | -02 | |

|---|---|---|---|---|

| Sewing shape |  |

|

|

|

| Thread trimmer | Upper thread trimmer | ○ | ||

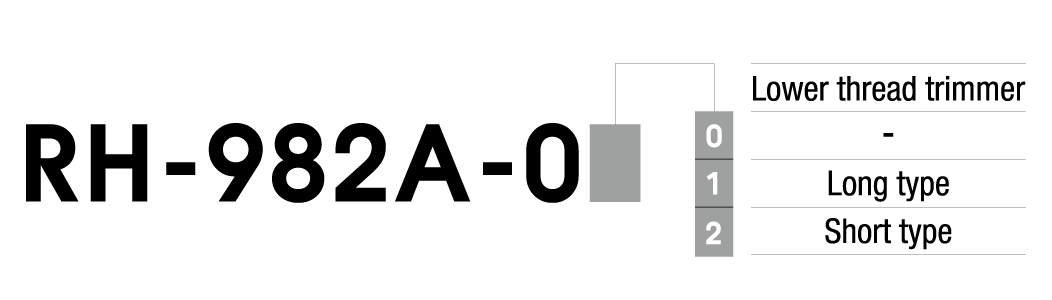

| Lower thread trimmer | None | Long type | Short type | |

| Main applications | Ladies wear | Men's wear, casual wear | Jeans | |

| Other applications | Men's wear, casual wear, jeans, trousers | Ladies wear,jeans,trousers | None | |

| Features | ・Buttonholes up to 50 mm long can be sewn. | ・The long thread ends can be securely held in the subsequent process. ・It is suitable for cases that require accurate short end or manual trimming. |

・The trouble of manual trimming and reduces consumption of the thread. | |

| Sewing length | Eyelet buttonhole : 8-50 mm Straight buttonhole : 5-50 mm |

Eyelet buttonhole : 8-42 mm Straight buttonhole : 5-42 mm |

L1422:14-22mm*3 L1826:18-26mm L2230:22-30mm L2634:26-34mm*3 L3442:34-42mm*3 |

|

| Length of work clamp (Standard) | 30mm | |||

| Length of hammer (Standard) | 22mm | 24mm | ||

| Length of hammer (Accessory) | 30mm | 28mm | ||

| Sewing speed | 1,000-2,500sti/min | |||

| Stitch pitch | 0.5~2.0mm | |||

| Zigzag width | 1.5-5.0 mm (Up to 4.0 mm in mechanical, up to 5.0 mm with zigzag width compensation) | |||

| Zigzag width (Factory setting) | 2.5mm | 3.0mm | ||

| Taper bartack length | 0-20mm | |||

| Height of work clamp | 12 mm as standard (Available up to 16 mm) | 16mm | ||

| Starting method | Foot switch (Two-pedal type), Hand switch (Two-lever type) | |||

| Feed mechanism | X, Y, θ intermittent feed mechanism (pulse-motors driven mechanism) | |||

| Needle | DOx558 Nm80 - Nm120 (SCHMETZ) | |||

| Needle(Factory setting)*5 | DOx558 Nm100 | DOx558 Nm90 | DOx558 Nm110 | |

| Upper shaft motor | AC servo motor 550W | |||

| Air pressure | Main regulator: 0.5 Mpa, Hammer pressure regulator: 0.4 MPa | |||

| Air consumption | 43.2 l/min. (8 cycles/min.) | |||

| Weight | Machine head: Approx. 120 kg, Operation panel: Approx. 0.6 kg, Control box: 8.8 kg | |||

| Power supply *2 | Shingle phase, 3-phase: 200V-230V Max. electric power 400VA | |||