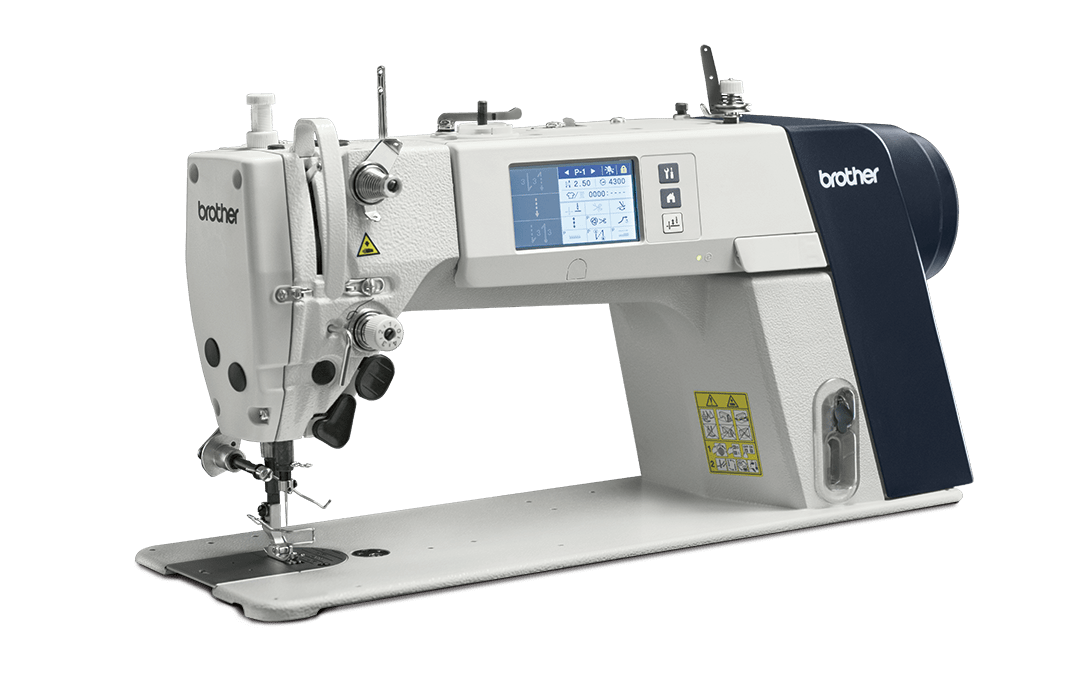

NEXIO S-7300A

NEXIO S-7300A

- Single Needle Direct Drive Lock Stitcher with Electronic Feeding System and Thread Trimmer

- ・Enhances productivity and quality sewing by DigiFlex Feed

- ・Needle breakage, material slippage, and puckering prevention

- ・Reduction of disposition of thread ends

- ・Offers a new value with Design Stitch

- ・Clogging at cross-over seam reduction・Equipped the color LCD touch panel for intuitive operation・Enhances the operability with new Hand Switch

Catalog, Manual, Parts-book Download

Information

Overview

Features

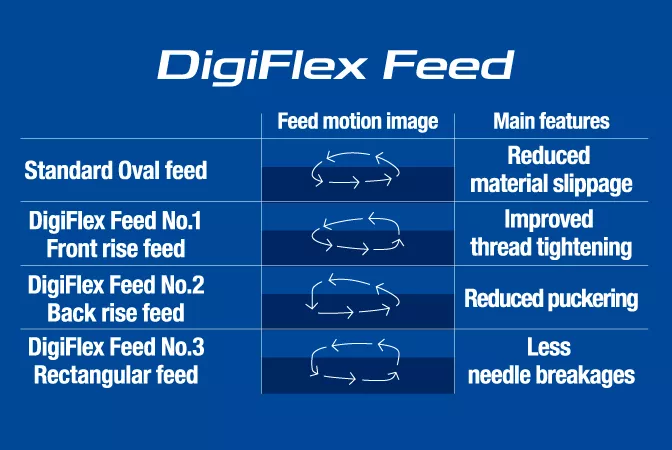

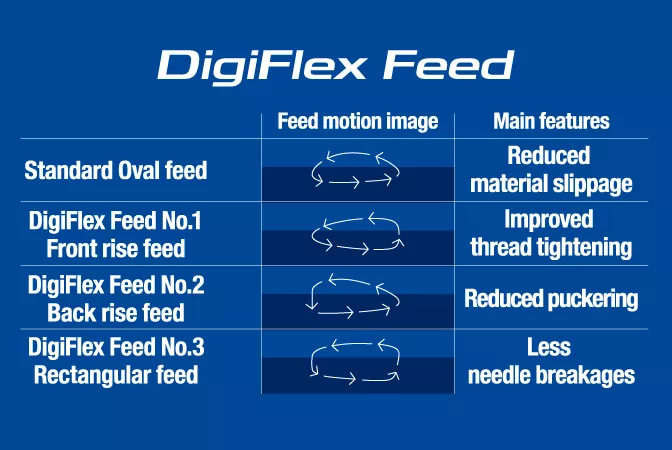

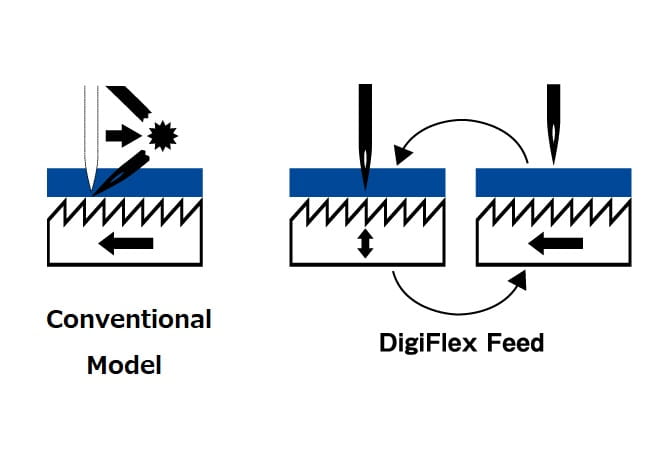

DigiFlex Feed, which is world's first equipped on S-7300A and highly evaluated in the

market,

digitalizes feeding system and resolves various sewing troubles without adjustment work.

- Improvement in the reduction of needle breakage and productivity.

- Simple select and smooth sewing without material slippage.

- Excellent sewing quality that's easy to get proper thread tension in accordance with several materials

Optimization of fabric feed timing by changing feed motion of DigiFlex Feed

Fabric can be feed at an appropriate timing so that needle won't break even during thick material sewing.

Change from mechanical control to stepping motor control by equipped DigiFlex Feed

Compared to conventional mechanical control, the stepping motor control makes the response of reverse sewing quicker and reduces needle breakage.

Equipped with needle prevent breakage function while reverse sewing

Sensing needle position and controlling proper feed timing that prevent from unreasonable reverse sewing as needle breaks automatically.

Short remaining thread by 3mm doesn't require after-cutting process

Minimizes the bird's nest at sewing start and short remaining thread min. 3mm.

The new double action thread trimming mechanism cuts the thread right under the needle hole, realizing the short remaining thread.

The disposition of thread ends after sewing can be reduced thanks to the new system. (Premier Spec.)

Oil staining prevention

You can choose minimum lubrication system or semi dry type. Oil leakage from the needle bar area can be prevented, realizing clean sewing and stain free garments.

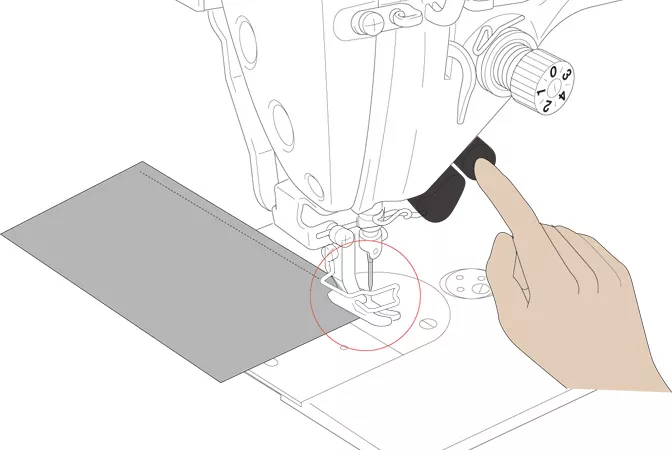

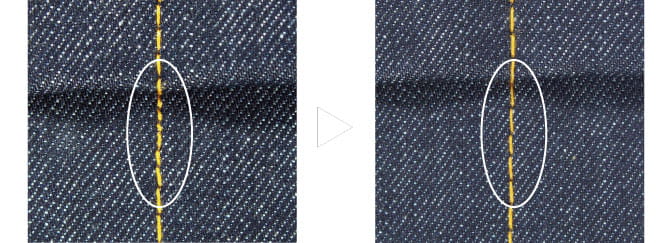

Clogging at cross-over seam reduction

Automatic material thickness sensor detects the thickness while sewing, helping reduce clogging at cross-over seam and needle breakage. S-7300A enables to correct stitch length automatically, when sensor has been detected cross-over seam, offering stable stitch length and high quality sewing for even unskilled-operator.

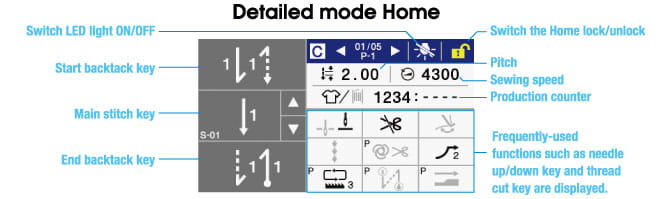

User-intuitive Color LCD with Touch Panel

Equipped the Color LCD with touch panel and indicates display items with illustration icons, offering user-intuitive operation.

For panel display, Easy mode Home(for operators) and Detailed mode Home(for mechanics) are available. Each mode is spotting the necessary and useful functions according to the users so they can grasp the needed information at a glance. Switching those modes can be set on the panel.

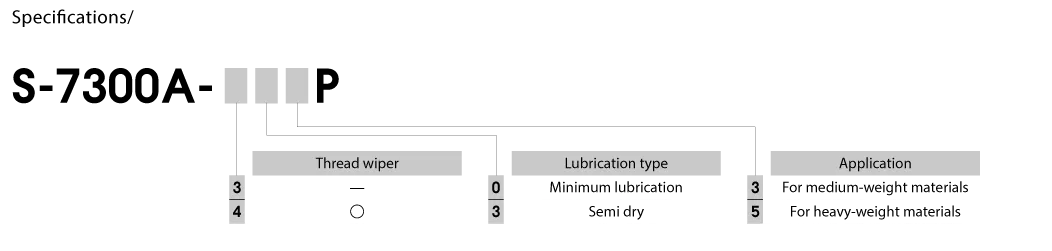

Specifications

| S-7300A | -603P, -603P | -903P, -903P | -605P, -605P | -905P, -905P | -633P, -633P | -933P, -933P |

|---|---|---|---|---|---|---|

| Lubrication type | Minimum lubrication | Minimum lubrication | Semi dry | |||

| Application | For medium-weight materials | For heavy-weight materials | For medium-weight materials | |||

| Max. sewing speed | Stitch length 4mm and under : 5,000 sti/min Stitch length 4mm and above : 4,000 sti/min |

Stitch length 4mm and under : 4,500 sti/min Stitch length 4mm and above : 4,000 sti/min |

Stitch length 4mm and under : 5,000 sti/min Stitch length 4mm and above : 4,000 sti/min |

|||

| Max. back tacking speed | 3,000 sti/min | |||||

| Max. stitch length | 5mm | Max 7mm (default setting: 5mm) |

5mm | |||

| Auto foot lifter | ー | Standard equipment | ー | Standard equipment | ー | Standard equipment |

| Presser foot height | Presser bar lifter: 6mm、Knee lifter: 16mm、Auto foot lifter:10mm | |||||

| Needle bar stroke | 31mm | 35mm | 31mm | |||

| Needle (DBx1・DPx5) | #11-#18 (Nm75-110) | #19-#22 (Nm120-140) | #11-#18 (Nm75-110) | |||

| Height of feed dog | 0.8mm | 1.2mm | 0.8mm | |||

| Weight | 34.5kg | 39.5kg | 34.5kg | 39.5kg | 34.5kg | 39.5kg |

| Motor | AC servo motor | |||||

| Power | 100-110V(*1), 200V-230V, 380V-400V(*1) under 450VA *1: The transformer is required. |

|||||