NEXIO BAS-342K

NEXIO BAS-342K

- ・Direct Drive Programmable Electronic Pattern Sewing with Cylinder Bed

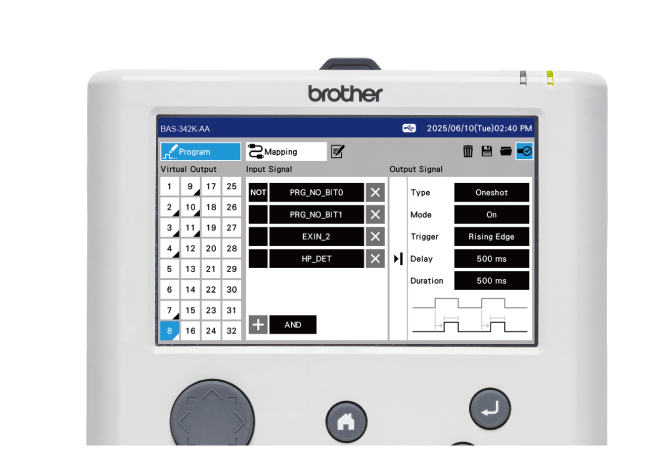

- ・Equipped with the DIGIFLEX TUNE function, which digitizes analog adjustments.

- ・The Upper thred tension sensou ,skip stitch detection,thread breakage delection,thread tension monitoring.

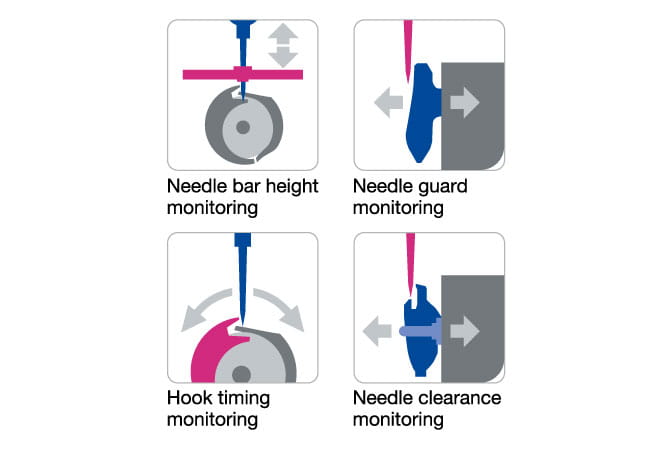

- ・Equipped with adjustment monitoring function to accurately detect sewing defects.

- ・Sewing area: 300×200mm

Catalog, Manual, Parts-book Download

Information

Overview

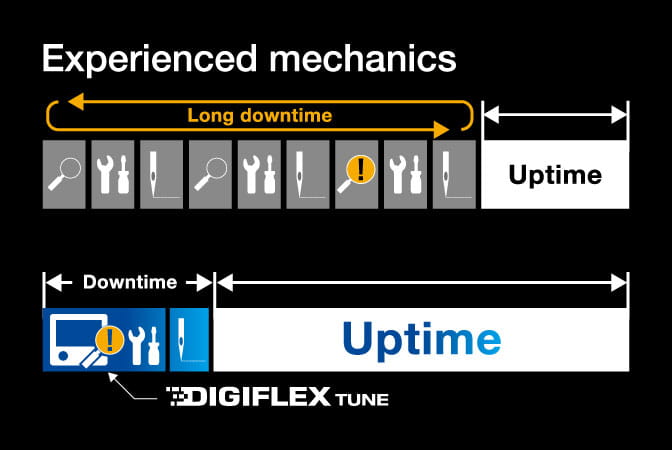

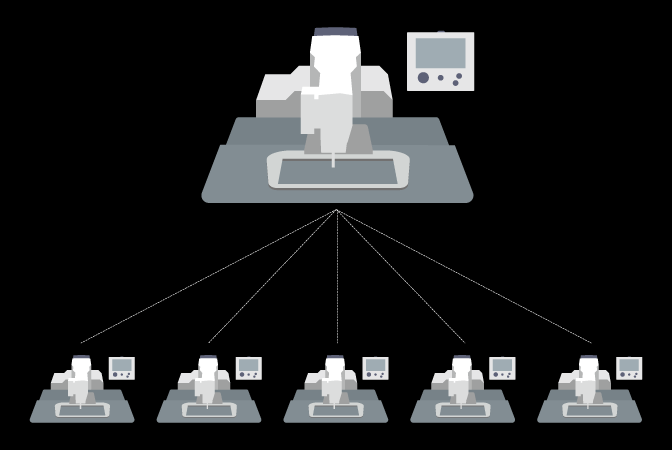

Sensing makes it clear how to handle sewing defects, minimizes downtime and increases productivity.

The adjustment time of the sewing machine due to poor sewing is greatly reduced by sensor monitoring technology. Appropriate adjustments depending on the cause of the sewing defect can be made just from checking numerical values on the panel.

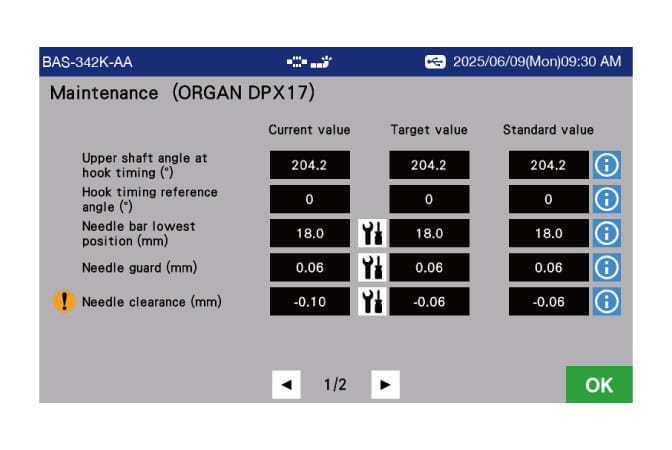

Digitalized analog adjustment to achieve precise adjustments.

Adjustments in increments of 0.01 millimeters are possible, eliminating variations in adjustments due to people and environments. The sewing machine adjustment, which was done visually or manually, will change to adjusting while checking the target value set on the panel and current value.

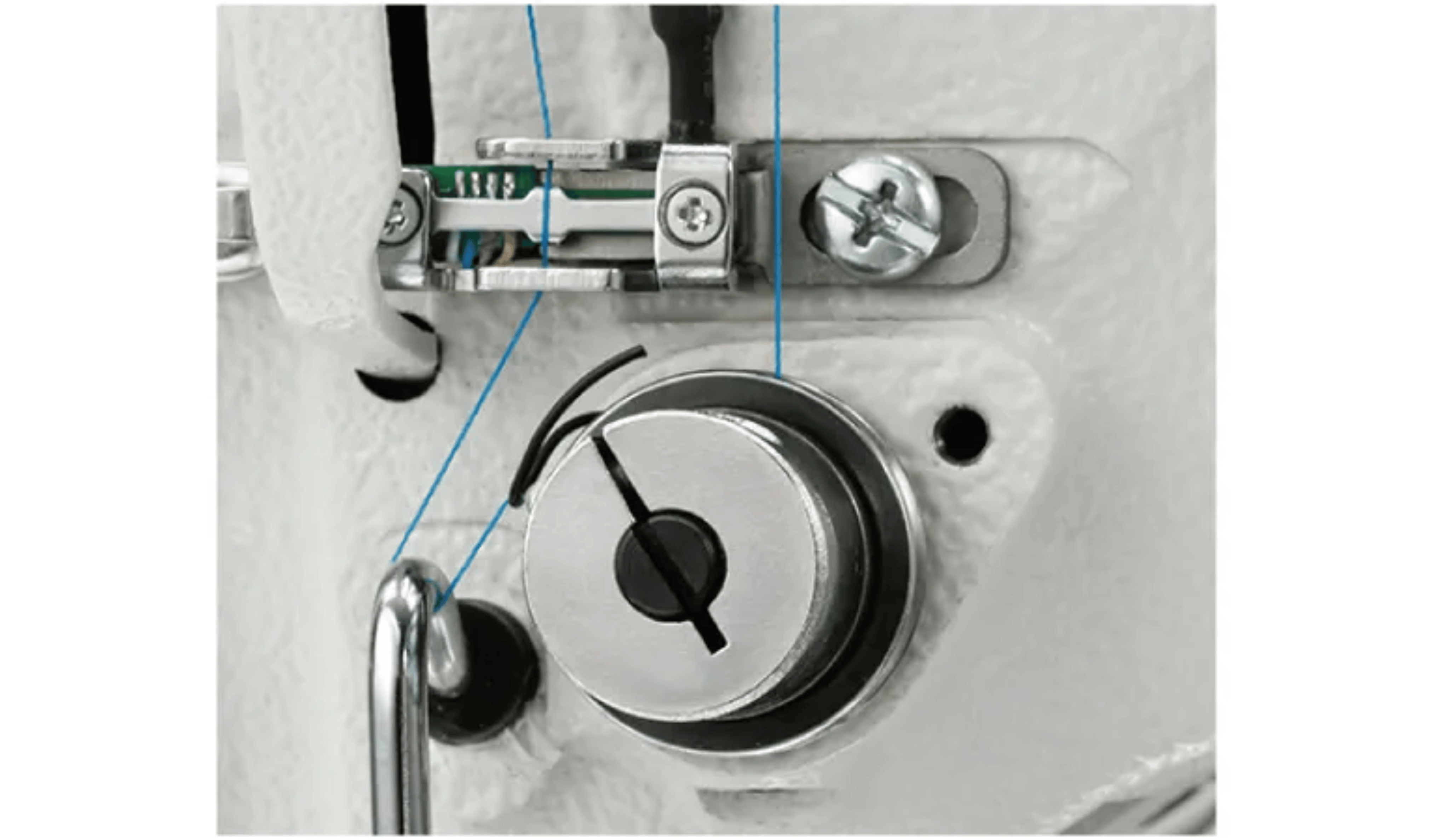

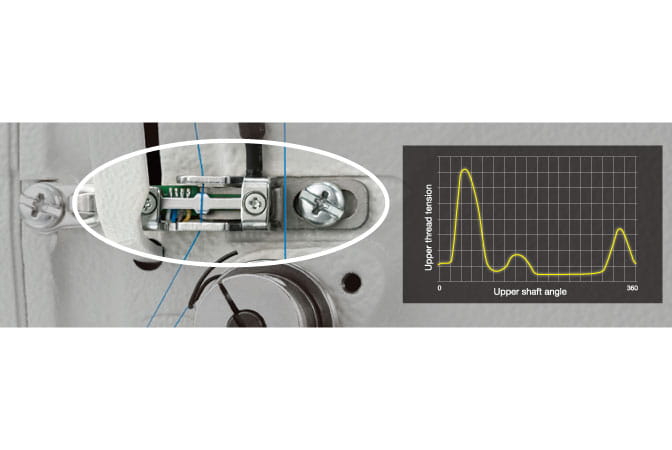

The Upper thred tension sensou ,skip stitch detection,thread breakage delection,thread tension monitoring.

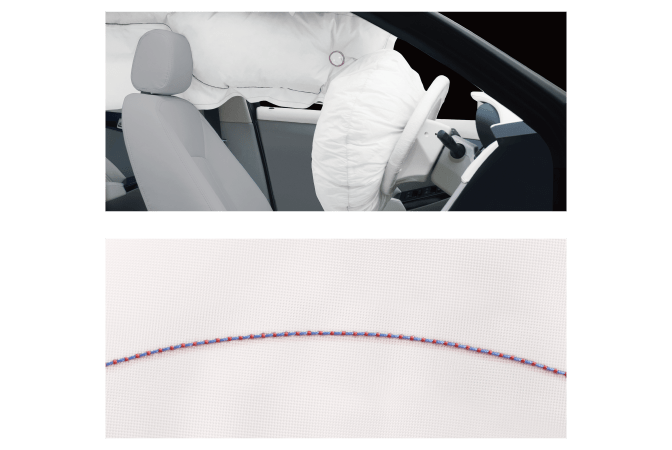

By using the upper thread tension sensor to detect skipped stitches, thread breakage, and monitor dynamic tension, sewing defects can be detected and defective products are prevented from moving on to the next process. By detecting sewing defects by detecting skipped stitch, thread breakage detection, and dynamic upper thread tension monitoring, defective products are prevented from flowing to the downstream process. By continuously monitoring the tension, we plan to add additional criteria for detecting other defects and abnormalities.

Features

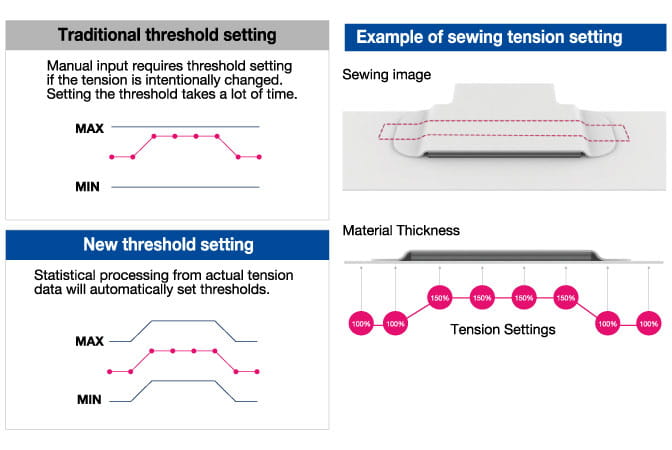

Thread tension monitoring

In addition to the conventional skip stitch and thread breakage detection, upper thread tension monitoring function has been added. The threshold based on the standard deviation can be automatically set for each stitch, allowing for easy and highly accurate detection. This technology can now detect sudden tension abnormalities during sewing.

Specifications

*1At 2,800 sti/min, the pitch should be 3.5 mm or less.

| BAS- | 342K |

|---|---|

| Stitch form | Single needle lock stitch |

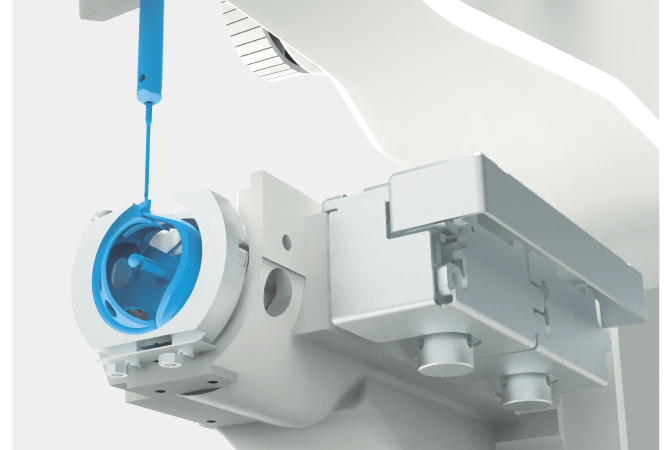

| Hook | Double-capacity shuttle hook |

| Max. sewing speed | 2,800sti/min*1 |

| Max. sewing area (W×D) | 300 x 200mm |

| Footprint (W×D) | 1,200 x 1,160mm |

| Feed mechanism | Intermittent feed (pulse motor drive) |

| Stitch length | 0.05-20.0mm (per 0.05mm) |

| Max. number of stitches | 100,000 stitches (per program) |

| Max. number of programs | 999 |

| Work clamp drive | Pneumatic drive |

| Work clamp lift amount | Max. 30mm |

| Work clamp | Integrated-type |

| Height of stepping presser foot | 27mm (highest needle stop position) |

| Stepping presser foot stroke | 0-10mm (per 0.1mm) |

| Thread wiper | Standard equipment |

| Thread trimmer | Standard equipment |

| Digital tension | Standard equipment |

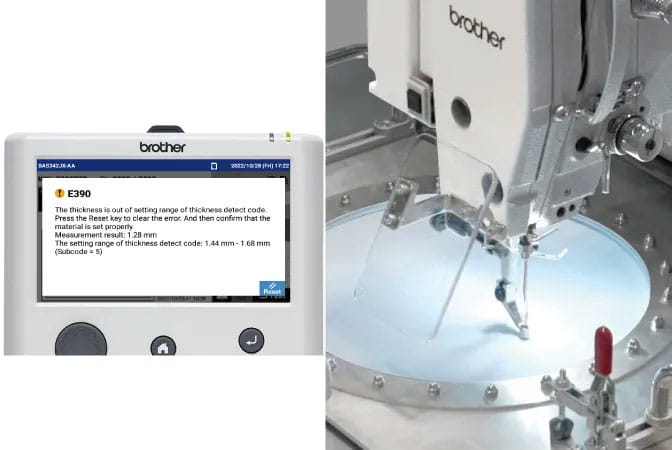

| Material thickness detection function | Standard equipment |

| Upper thread tension sensor | Skipped stitches detection,thread breakage detection,thread tension monitoring |

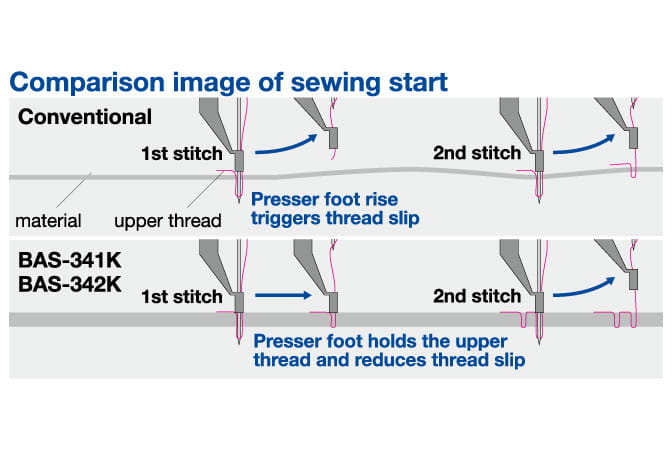

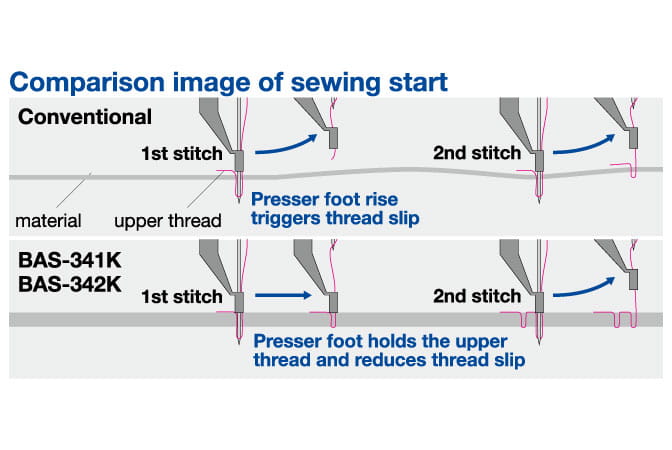

| Upper thread slip prevention function | Standard equipment |

| Needle bar position monitoring | Standard equipment |

| Needle guard monitoring | Standard equipment |

| Meeting timing monitoring | Standard equipment |

| Needle gap monitoring | Standard equipment |

| Oil level monitoring | Standard equipment |

| Data storage media | Internal flash memory (data addition is available with external memory) |

| Motor | AC servo motor |

| Weight | Machine head: Approx. 175kg Control box: Approx. 15kg |

| Power | 1-phase: 200V-240V 450VA |

| Air pressure/Consumption | 0.5MPa, 1.8l/min |