Data Trend from NEXIO SYSTEM - Oct, 2020

Invisibility of the machine operation became a thing of the past.

To achieve everyday production target, factory is conducting several activities such as, time study, line balancing, and training to the operator.

However, have you ever seen the data of the sewing machine operation ratio?

We understand this situation that we cannot be able to visualize the data is an issue.

To visualize and analyze, we have conducted survey in the market and collected over 100 factories with total 760 machine data.

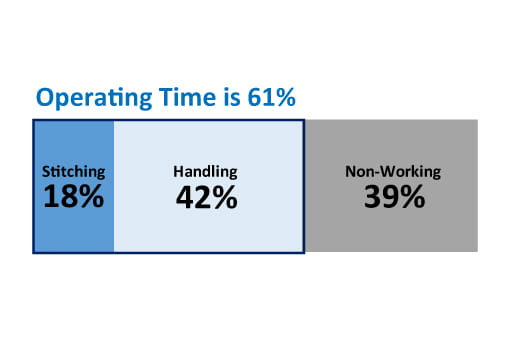

Average operation ratio is 61% and needle time is only 18%.

To segregate sewing operation, there are 3 types of time.

1. Needle time

2. Handling time

3. Other

We think ratio of the those 3 are related to the health of factory production strongly.Each factory should have trend of the operation ratio and that number must have variety of the reasons depending on the factory or production line.To mention several types of reasons of less operation ratio are, operator might be waiting for next pieces, operator is not skilled to produce stably, or might be the health condition of the operator is not well.

The key is, 1st we need to grasp the hourly or daily changes of production on real time basis and once there is problem we take immediate action for the improvement.

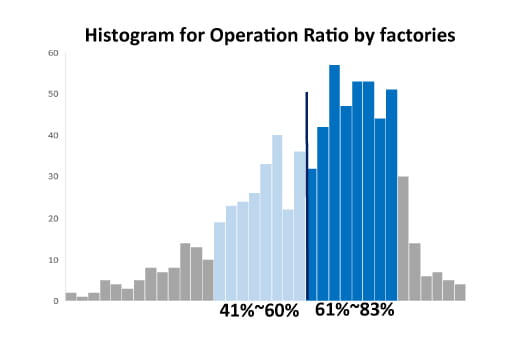

Where is your operation ratio at?

Left chart is a data which Brother has analyzed from the 1-Line assessment through 90 factories. To study this histogram, we can see there are 2 condensed areas.1 is below average around 40% to 60% of operation ratio. The other is between 60% to 80%.Use as your reference of 1-Line Assessment result to judge whether your operator is utilizing equipment properly or not.

Why don’t you try to visualize your actual operator capability?

Special offer against covid-19

As a initial step, why don’t you try Brother's new service to visualize your actual operator capability?

Brother is now providing new free service "1-Line Assessment" which our specialist visits the factory to prepare factory efficiency report.

We will check actual operator’s cycle time directly from sewing machine and compare with your standard time to visualize your problem to support improvement.

We are now receiving over 200 request, and October and November is almost full!

Sign up today and find out machine utilization!

Our specialist will contact you once you have applied. We will explain the details of IoT system and answer your questions.

Then, schedule a visit to your factory accordingly. Please do not hesitate to contact us.

Please read the Terms of Use here and send the application if you agree to it.

Learn what NEXIO SYSTEM is

Link to YouTube

IoT applicable sewing machine - NEXIO series product information

Backnumber

-

73% sewing machines were not meeting the standard time

-

Brother's new service against COVID-19

-

3 tips to increase productivity in small-lot production

-

Ranking of single needle lockstitch operating ratio

-

Production has come back to 70% after COVID-19

-

Garment industry lost over 70% of functions by COVID-19

-

Loss of 110 hours per sewing machine.