Data Trend from NEXIO SYSTEM - Sep, 2020

Have you ever reviewed way of setting standard time?

There are so many reasons for delay of the production, starting from, lack of manpower, material flow in the factory, delay to machine allocation etc…

We, Brother, found that “difference between standard time and operator capability” seems to be another big reason for the production delay through conducting our new service “1-Line Assessment” to garment factories in Bangladesh, India, Vietnam.

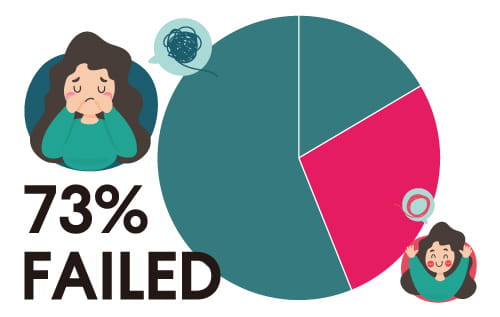

73% sewing machines were not meeting the standard time

We had conducted 41 survey and took 358 machines data. From the data, we came to know 73% (259 machines) of the process was not meeting the standard time which set by factory.

What makes the standard time wrong?

We assume there are several causes for this issue.

1. Standard time which we set from past study or request from buyer is not reflecting operator capability

2. New design and material is giving complexity to process

3. Time study is not accurate

Revision of the way of setting standard time will increase communication between operators. In addition to that, it will gives you proper production planning which connects to reliability from the buyers and new orders.

Proper standard time setting gives you stable production

To set proper standard time, what we should do is following points.

1. Conducting time study constantly to understand current situation.

2. Increasing the data samples to enhance reliability.

3. Accumulate and stay updated the data for next production.

Why don’t you try to visualize your actual operator capability?

As a initial step, why don’t you try Brother's new service to visualize your actual operator capability?

Brother is now providing new free service "1-Line Assessment" which our specialist visits the factory to prepare factory efficiency report.

We will check actual operator’s cycle time directly from sewing machine and compare with your standard time to visualize your problem to support improvement.

We are now receiving over 200 request, and September and October is almost full!

Sign up today and find out machine utilization!

Our specialist will contact you once you have applied. We will explain the details of IoT system and answer your questions.

Then, schedule a visit to your factory accordingly. Please do not hesitate to contact us.

Please read the Terms of Use here and send the application if you agree to it.