T-8452D

T-8452D

- ・User- intuitive color LCD display touch panel

- ・Productivity improvement with IoT capabilities

- ・Equipped with needle breakage prevention function while reverse sewing

- ・USB port on operation panel

Information

Overview

User- intuitive Color LCD Display Touch Panel

The Color LCD display touch panel display items with illustration icons, offering easy user-intuitive operation. There are three types of operator panel display. All the detailed home screen, quick home screen and easy home screen are easy to use without concern for panel operation.

Equipped with needle breakage prevention function while reverse sewing

Powerful 550W motor outputs large amounts of torque even at slow speeds so that strong needle penetration force can be obtained. This allows accurate sewing of heavy materials and joints. If the needle penetration resistance increases, such as when sewing heavy materials and materials with joints, vibration control (intermittent impact) automatically increases the penetration force.(Patent pending)

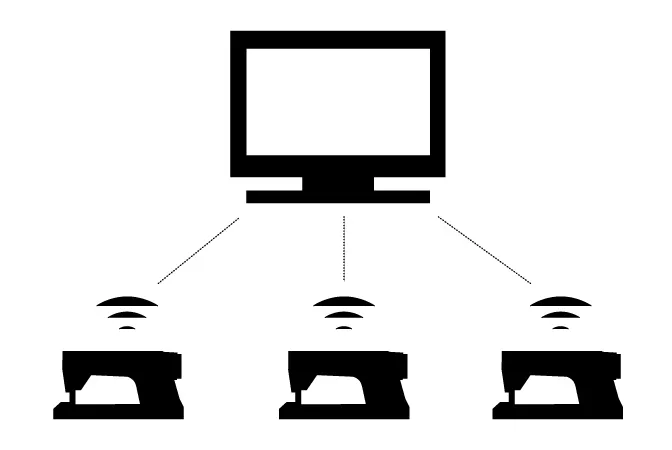

Productivity improvement with loT capabilities

This model is loT applicable. The visualization by connecting sewing machine and computer technology enables the customer to analyze, manage processes and speed up productivity improvement and maintenance work. *It is applicable for Brother’s IoT system. For more information, please refer to the catalog of “Brother Industrial Sewing Machine Network System”.

Features

We thoroughly investigated the cause of the needle breakage and needle point crushing problem that frequently occur in thick fabric backstitching and equipped this model with the function to prevent needle breakage. In addition, the quick back switch is located at a position where the operator can easily press, contributing to improved productivity.

Cam adopted in the lateral position adjustment mechanism for the rotary hook base allows easy fine adjustments for clearance between the needle and rotary hook point can easily be made. This greatly increases the efficiency of replacing gauge parts. Furthermore, a needle drop correction function (sideways) is provided, so that the needle drop position can still be adjusted to the center of the needle hole even if using commercially-available gauge parts. The gauge parts for previous models can still be used without any changes.

This model is loT applicable. The visualization by connecting sewing machine and computer technology enables the customer to analyze, manage processes and speed up productivity improvement and maintenance work. *It is applicable for Brother’s IoT system. For more information, please refer to the catalog of “Brother Industrial Sewing Machine Network System”.

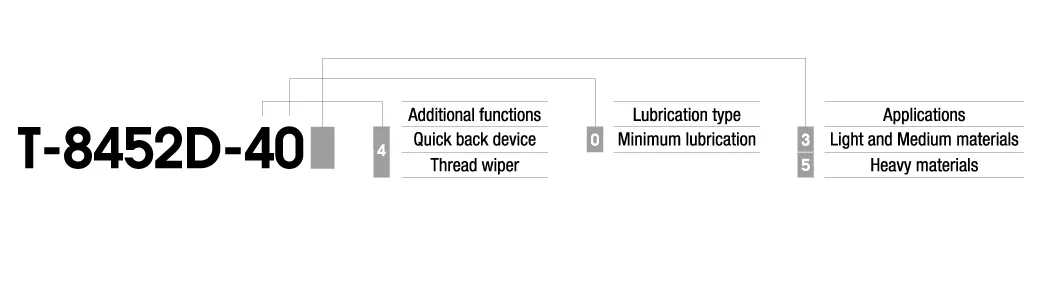

Specifications

| T-8452D | -403 | -405 |

|---|---|---|

| Lubrication type | Minimum lubrication | |

| Application | Light materials

Medium materials |

Heavy materials |

| Max. sewing speed | 3,000 sti/min | |

| Needle | DPx5

(#14) |

DPx5

(#22) |

| Max. stitch length | 5.0mm | |

| Presser foot height | 7.0mm | |

| Start backtacking and continuous backtacking speed | 250〜1,800sti/min | |

| End backtacking speed | 1,000sti/min | |

| Height of feed dog | 1.0mm | |

| Arm pocket size | 120.0 mm x 264.0mm | |

| Arm bed size | 517.5mm x 178.0mm | |

| Bobbin winder | Included in machine arm | |

| Machine head drive | Direct drive mechanism | |

| Motor | AC servo motor (550W) |

|

| Weight | Machine head : 47kg

Control box : 7.7kg |

Power | Single-phase, 3-phase: 200V-230V Max. electric power consumption 500VA |