NEXIO BE-438HX

NEXIO BE-438HX

- Electronic Direct Drive Lockstitch Button Sewer (Short Remaining Thread Spec.)

- ・Productivity Improvement by World's Top-class Sewing Speed and IoT

- ・Reduction of disposition of threads ends (short remaining thread)

- ・Beautiful and Highly-reproducible Sewing Quality by Digital Tension

- ・Set Button Smoothly

- ・Superior Usability as Everyone can Use Easily and Reliability・Clean Sewing with Semi-dry Type

Catalog, Manual, Parts-book Download

Information

Overview

Beautiful sewing quality

64 sewing patterns have already been set and can be selected. It's capable of various fine sewing patterns as well.

User- intuitive Color LCD with Touch Panel

Equipped the Color LCD with touch panel that indicates display items with illustration icons, offering use-intuitive operation. It is very easy to set the cycle program, along with sewing patterns, sewing speed, and magnification. The upper thread tension can be stored easily as user programs.

Features

Specifications

| BE-438HX | |||||

|---|---|---|---|---|---|

| Application | Button attaching | ||||

| Lubrication | Semi-dry | ||||

| Max. sewing speed | 2,800sti/min | ||||

| Max. sewing area | Max.6.4x6.4mm | ||||

| Dimensions of buttons that can be sewn | Outer diameter of buttons 8-30mm*1 | ||||

| Stitch length | 0.05~6.4mm | ||||

| Feed mechanism | Y-θintermittent feed mechanism (pulse-motor driven mechanism) | ||||

| No. of stitches | Variable (Refer to "Program List" for details on the number of stitches for sewing patterns that are already preset) | ||||

| Max.No. of stitches | 5,000 stitches/pattern | ||||

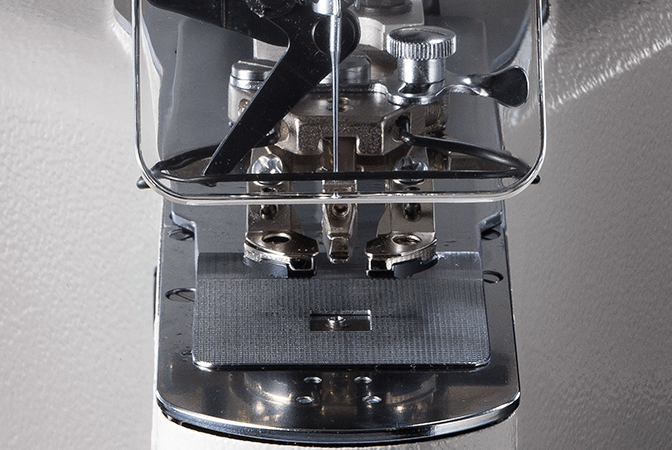

| Work clamp lifter | Pulse motor drive system | ||||

| Work clamp height / Button clamp height | Max. 13mm | ||||

| Rotary hook | Shuttle hook (double shuttle hook, optional) | ||||

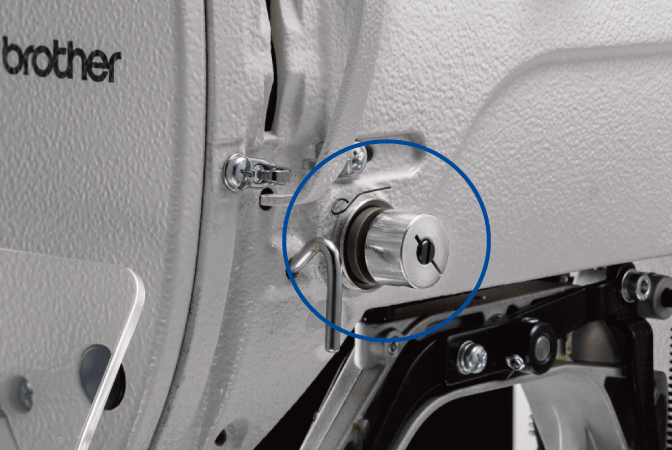

| Digital tension | Standard equipment | ||||

| Thread wiper | Standard equipment | ||||

| Thread trimmer | Standard equipment | ||||

| Thread nipper | Standard equipment | ||||

| Data storage method | Internal flash memory (Data addition is available with external memory) | ||||

| No. of cycle programs | 30 cycle (50 programs for each cycle) | ||||

| No. of stored data | 64 sewing patterns are set already | ||||

| (up to 512 patterns can be added. Total number of stitches of stored data which can be added is within 500,000*2) | |||||

| Motor | AC servo motor 550W (Direct Drive) | ||||

| Weight | Machine head: Approx. 57kg, Operation panel: Approx. 0.4kg, Control box: Approx. 9kg | ||||

| Power supply | Single-phase 100V/200V, 3 phase 220V/380V/400V 400VA (For single-phase 100V and 3-phase 380V/400V, the trans box is require | ||||