Problems of Owner

Learn how the Nexio System increases productivity through real-world situations.

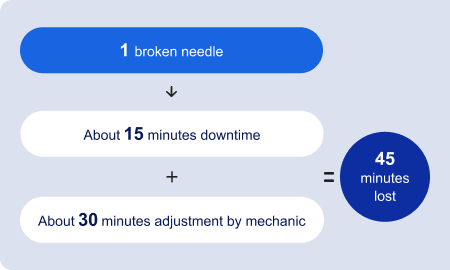

There are various factors that reduce the operating rate of sewing factories, but the most important one is probably "broken needles." When a sewing machine needle breaks, not only does it require needle replacement, but it also requires checking to see if the broken needle is mixed into the product, which greatly reduces work efficiency.

Reduce needle breakage to increase operating rates!

When producing a wide variety of items, the sewing machine settings need to be adjusted many times and high sewing skills are required. Depending on the skill level of the workers, sewing defects such as puckering and uneven stitching will increase. Defective products will lead to a loss of credibility for the factory.

To improve quality, a sewing environment that is user-friendly is essential!

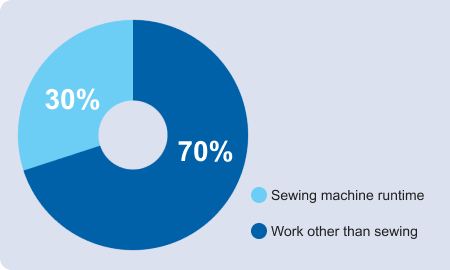

To maintain uniform quality, all sewing machines need to be adjusted in the same way. However, the more machines there are, the more time and effort it takes. Every time an adjustment is required, it becomes a major cause of reduced productivity.

To improve productivity, minimize the time the sewing machine is stopped!

Problems will be resolved by "DigiFlex Feed"

Learn how “DigiFlex Feed” can help mechanics

1

Needle breakage prevention functionincreases operation rate!

DigiFlex Feed feeds the fabric at the right timing to prevent the needle from breaking. Even when sewing thick materials that are prone to needle breakage, the fabric is not fed when the needle is inserted into the fabric, so the needle is not burdened.

This reduces needle breakage and improves operation rate.

This reduces needle breakage and improves operation rate.

2

With the optimal feed function,anyone can maintain high quality!

DigiFlex Feed allows you to select from four different trajectories to determine the appropriate timing for thread tightening depending on the fabric.

By simply selecting the settings, anyone can now sew with consistent quality, even in difficult processes that previously relied on the skills and experience of the worker.

By simply selecting the settings, anyone can now sew with consistent quality, even in difficult processes that previously relied on the skills and experience of the worker.

3

Reduce unnecessary setting work andimprove productivity!

DigiFlex Feed digitally manages the fabric feed settings that were previously done manually.

Even new employees can set it up quickly with simple button operations. This minimizes sewing machine downtime and helps improve line productivity.

Even new employees can set it up quickly with simple button operations. This minimizes sewing machine downtime and helps improve line productivity.

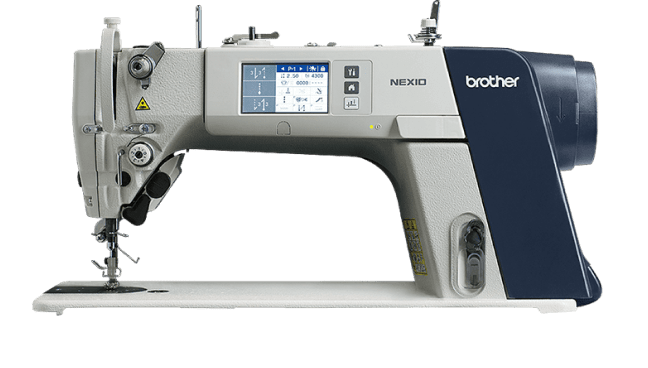

Product Lineup

- Travel of each axis(mm): X200 Y440 Z305

- Travels (A, C) (deg.): A: -30~120, C: 360

- Max. spindle speed(min-1): 10,000/ (Optional) 16,000/ 27,000/ 10,000 high- torque

- Tool storage capacity(pcs.): 14/21

- Max. turning spindle speed (min-1): 2,000

- Electronic feed mechanism used for fabric feed

- Realizing high quality stitching

- Reduces troubles such as needle breakage and improves productivity

- Proposing new value through design stitching

- Easy-to-use simple operation panel

![ADVANCED Panel Operation 01 [Brother KE-430HX & BE-438HX]](https://img.youtube.com/vi/0Lgn0Q1vikM/0.jpg)